Moffett Automation was founded in 2017 with a small, dedicated team and a vision for innovation and global impact, writes Shane Clarke.

“Since those early days our ambitions have driven remarkable growth: today, we are proud to employ over 100 talented professionals who contribute to our expanding portfolio of industry-leading solutions. Our engineering excellence has garnered significant recognition, highlighted by the 2022 Manufacturing Supply Chain Awards. This momentum continued in 2023 when Ernst & Young honored our Managing Director, Sam Moffett, with the prestigious ‘Entrepreneur of the Year’ award in Ireland. Building on this achievement, Sam was subsequently nominated as an International Entrepreneur of the Year contender in 2024.

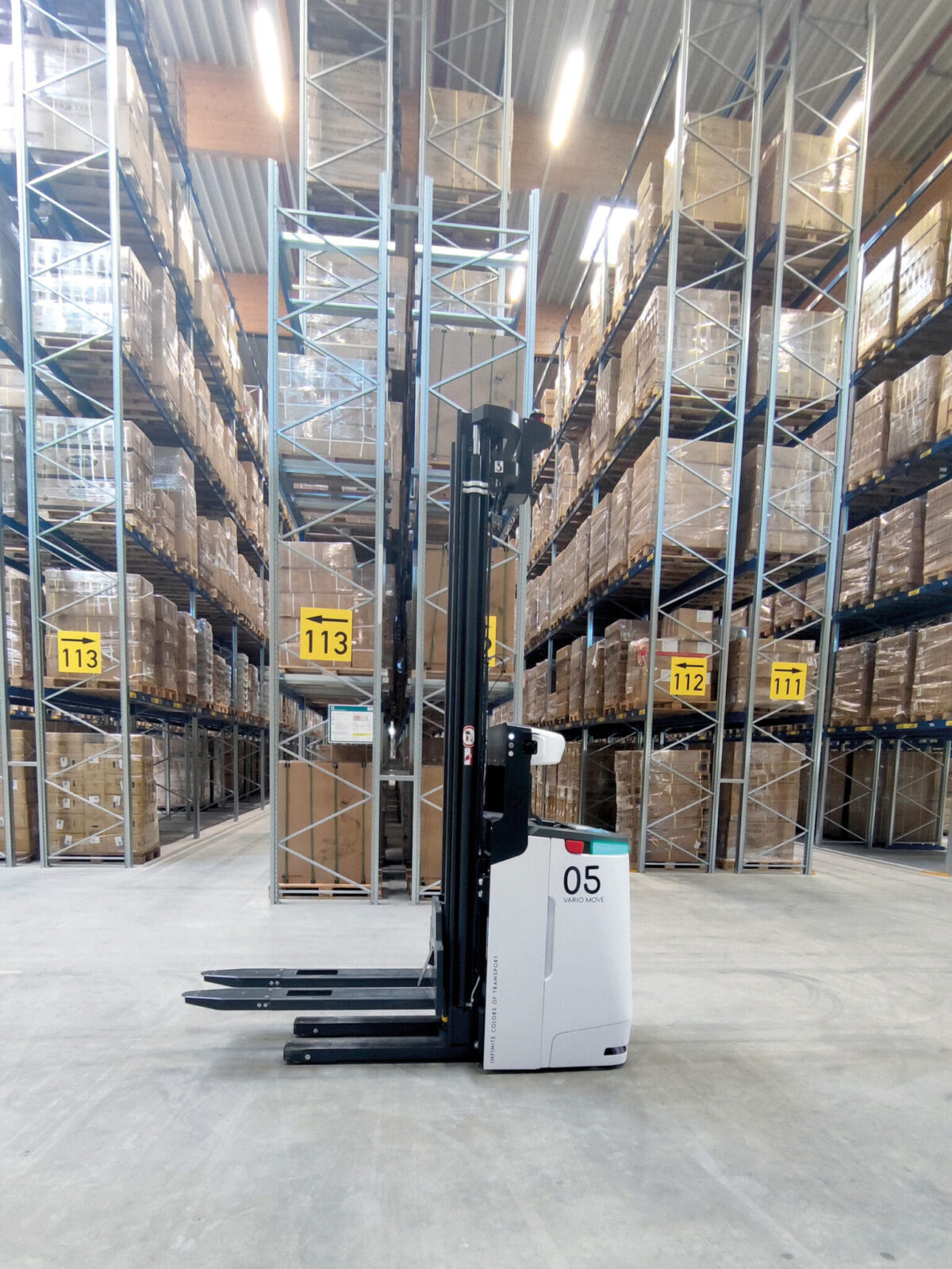

“As our expertise and reputation have grown, so too has our global reach. Our Moffett Taxi Systems (pictured) have been implemented in over 20 locations worldwide, establishing our presence as a trusted partner in automation on an international scale. Each system reinforces our commitment to excellence and demonstrates our ability to deliver high-quality, cutting-edge technology solutions that meet the evolving needs of the warehouse and logistics industries. Our global footprint continues to expand as we work with partners and clients across multiple sectors and territories, ensuring that our solutions remain at the forefront of efficiency and reliability.

“Our fully automated warehouse storage solutions are powered by our highly regarded four-directional Moffett Taxi pallet shuttle. This system revolutionizes warehousing by optimizing space, reducing manual labor, and increasing operational efficiency. We take great care to understand the unique needs of each customer, designing and implementing bespoke pallet storage solutions that align perfectly with their requirements. Our customer-centric approach ensures that each solution maximizes productivity and streamlines operations.

Seamless movement

“The Moffett Automation VTUs (Vertical Transfer Units) allow our taxis to move seamlessly in all directions. These VTUs enable the taxis to travel between multiple levels, ensuring that any taxi can carry any pallet to any storage space within the system. This innovative flexibility eliminates bottlenecks and enhances the overall efficiency of warehouse operations. Our customers benefit from a system that not only optimizes storage capacity but also delivers unparalleled speed and reliability.”

Each Moffett Taxi is engineered to handle heavy pallet loads of up to 1500kg, demonstrating its robust and durable design. The system is also built to withstand challenging environments, operating efficiently in temperatures as low as -25°C, making it ideal for a wide range of industries, including food storage and pharmaceuticals. The taxis boast an operational period of 8 hours in ambient storage conditions and 6.6 hours in chilled storage, ensuring that they maintain high performance levels even in the most demanding settings.

“Our cutting-edge software plays a crucial role in the functionality and reliability of our automation systems, adds Clarke. “It enables remote monitoring and control, allowing for real-time adjustments and preventative maintenance. Key features include automated heat sensor monitoring, motor deceleration and acceleration adjustments, and remote operation. This guarantees rapid response to any technical issues, minimizing downtime and preserving system integrity.

Pallet Taxi

“One of the defining aspects of Moffett Automation is our commitment to in-house manufacturing. The Moffett Taxis, VTUs, and conveyors are built at our factory in Ireland, giving us the control to maintain the highest standards of quality and innovation.

“Looking forward, Moffett Automation remains dedicated to pushing the boundaries of warehouse automation. Our ongoing investment in research and development ensures that we continue to lead the industry with pioneering solutions. By leveraging cutting-edge technology, engineering excellence, and an unwavering commitment to customer satisfaction, we are shaping the future of automated storage and logistics on a global scale.”

similar news