To ensure that Witron remains a strong partner for its customers and employees in the future and can cope with growth, company founder and owner Walter Winkler decided at the beginning of 2019, to expand the manufacturing capacity of its Parkstein facility by 120,000 sq m to a total of 220,000 sq m, which corresponds to an investment volume of around €200m. This is currently the largest privately financed construction project in northern Bavaria.

After a record-breaking planning and construction period of more than 2.5 years and just in time for the company’s 50th anniversary, highly dynamic conveyor system elements and control cabinets will be manufactured in the new Werk II Nord facility from the beginning of September 2021. This expansion will create up to 1,800 attractive new jobs in Parkstein for IT and PLC specialists, project staff, design engineers, metalworkers, mechatronic engineers, and electricians.

The opening was duly celebrated with selected guests in compliance with the current regulatory conditions. In his festive speech, Minister Albert Füracker described the company as “shining example for Bavaria”.

“Leading-edge solutions and successful projects were and still are the driver for the strong growth of the Witron Group,” says Walter Winkler in his welcome speech. “To reliably cover this high demand in terms of quality and quantity in the future, we have decided to make this investment. In addition, this step makes it possible to permanently secure jobs in the region as well as in the subsidiaries in Europe, North America, and Australia, and to remain technologically up-to-date.

“Innovation and motivated, well-trained employees have been a supporting pillar of Witron since the company’s foundation. A company should never be interchangeable. Not in terms of the solutions it offers and certainly not in terms of its corporate culture and the commitment of its employees. Only then will it be successful in the long-term. Natural intelligence is just as important as artificial intelligence.”

Albert Füracker, Bavarian State Minister for Finance and Home Affairs ,praised Witron as “added value for the Upper Palatinate and a shining example for Bavaria”. Furthermore, Füracker emphasised the lived-out Witron culture based on tradition and progress: “Witron has been a down-to-earth company for 50 years, which still modestly calls itself a ‘hidden champion’, but is a true ‘real champion’ – with Walter Winkler as an entrepreneurial personality who is characterised by creativity and passion.

“A personality who doesn’t just have ideas and plans in his head, or perhaps even as a sketch on paper, but who implements them consistently and, above all, successfully – for the benefit of the customers, the employees, and the company.” According to the Minister, Witron’s permanent success is “the result of inspiration and transpiration”.

“Only a few months after the decision to plan and build the facility, the first earthworks already started,” said Water Winkler. “Prerequisite for this was also the pragmatic cooperation with the local authorities, architects, all suppliers, as well as the responsible general contractor. Thanks to many hardworking hands and the great commitment of all parties involved, the inauguration ceremony of Werk II Nord can be properly celebrated in the anniversary year after a construction period of just under two years.”

Witron currently employs 4,800 staff members, of which more than 2,000 work at the headquarters in Parkstein. In the next two years, this figure will rise to 7,000 employees worldwide, and the customer orders for this have already been placed. Sales of almost €1bn are expected for the 2021 fiscal year.

“Due to this positive outlook, it is mandatory to significantly expand manufacturing resources and hire additional employees,” explains Winkler. “We will then be able to offer up to 1,800 attractive new jobs in Parkstein – for IT specialists, PLC and project staff, design engineers, mechatronic engineers, electricians, and metalworkers.”

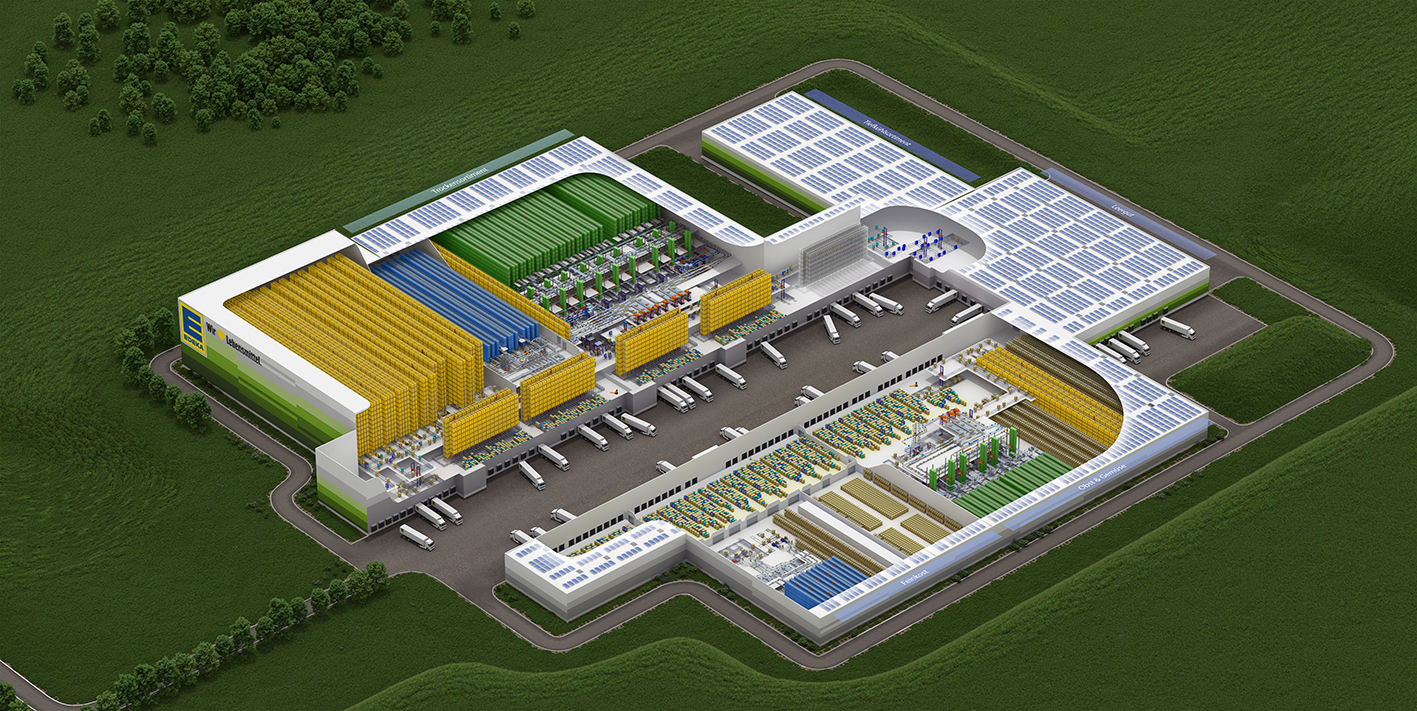

The general contractor for logistics from Parkstein has been manufacturing its own highly dynamic and energy-efficient pallet, tote, and tray conveyor system elements since 2005. The central production for all projects worldwide takes place in Parkstein. Manufacturing resources were already significantly increased in 2010, 2013, and 2018. In the new Werk II Nord facility, the area for the construction of conveyor system elements alone including galvanisation covers 87,000 sq m.

An additional 12,000 sq m are planned for the production of control cabinets. The storage capacities in the automated warehouses are designed to accommodate 10,500 pallet and 23,750 tote storage locations. The maximum building height is 11m. For reasons of space optimisation, storage will largely be below ground level.

The machine park uses the latest manufacturing technology such as laser-punching-bending machines or a large area for galvanic surface finishing. This enables a wide range of manufacturing operations and thus the highest quality down to the last detail. Production is more reminiscent of a manufactory than a production facility. This is because the final assembly of the conveyor elements takes place at production workstations using exactly tailored work processes.

All production workstations have an attractive and ergonomic design and provide all necessary components to completely manufacture the various elements. Production control and parts supply are supported by a Kanban system in connection with automatic pallet, tray, and tote warehouses. The individual production and storage areas, including receiving and shipping, are precisely linked with each other in a transparent, highly optimised material flow.

Instead of wiring motors, control, and drive units at the project site of the respective customer, this work is already done during the manufacturing process in an optimal working environment. High product quality, shortened commissioning times, and efficient interaction between controllers, sensors, and the PLC and IT components developed in-house by Witron without any interface problems are the result.

“We realise projects in a system-relevant industry sector,” emphasised Winkler. “Our solutions supply more than 100 million people daily with food and many important everyday necessities via stores or online – economically, ecologically, and socially. Numerous customers worldwide, especially from the food sector, rely on our project experience and technology know-how such as Witron’s patented OPM/COM technology.”

OPM/COM is considered the most successful fully automated picking system for cases across the globe.

Winkler highlighted the company’s strengths: “In addition, our customers – and we are particularly proud of this – rely on the values and culture that make the family company Witron so unique: Rolling up one’s sleeves, keeping promises, being credible, reliable, and predictable, staying down to earth. The entire Witron Group is aware of this responsibility every day. And with the additional opportunities that Werk II Nord offers, we are rising to this challenge – today and in the future, for the benefit of our customers and employees.”