Many packaging system owners who fix and package goods ready for dispatch by using stretch film for trans-shipment on pallets have been unsettled by a new packaging law in force since the beginning of 2019. Its aim is to avoid waste and increase recycling. Therefore, many films will contain more recycled material in future, which might considerably change their properties and also the handling.

Can the owners of packaging systems continue with the use of their systems? Yes, says Beumer Group.

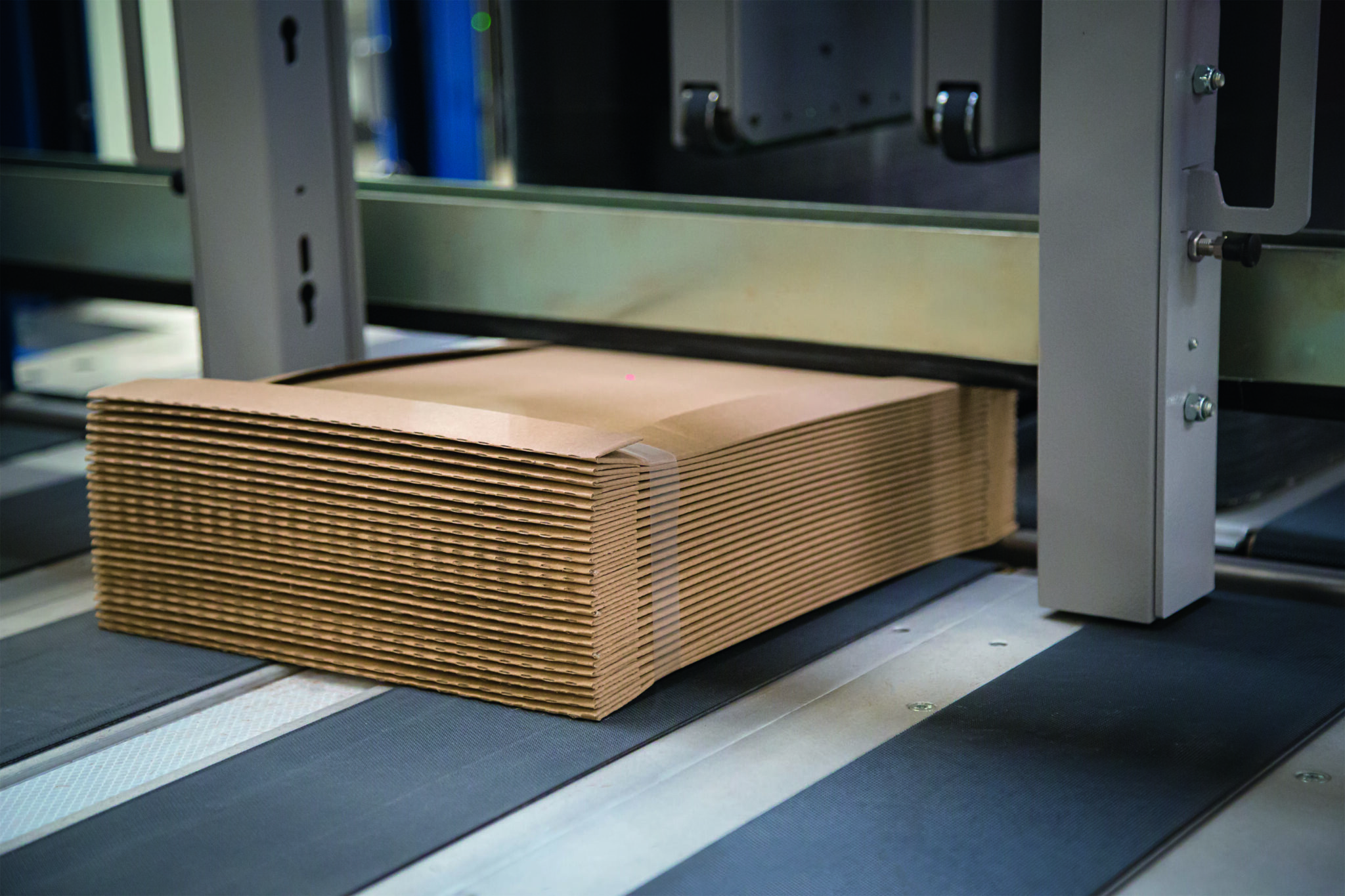

“At the centre of the packaging lines we install with our customer’s is the high capacity Beumer stretch hood A packaging system,” says Jörg Spiekermann, sales manager for palletising and packaging systems in the Consumer Goods area of Beumer Group. No matter if it is washing machines, paint buckets, barrels or champagne boxes on pallets: the system always covers each product efficiently with a highly elastic stretch hood.

This is also possible if the content shall not come in contact with the surface of the container, for example. This is the case for lubricants and adhesives, antifreeze, resins, brake cleaners, as well as for bulk material such as pellets. The inside of the barrel or of another container is lined with a film hood.

“During trans-shipment and outside storage, the merchandise is protected reliably against environmental influences such as sunlight, dirt and humidity,” Spiekermann explains. “Furthermore, the packaging ensures that the products remain stable on the pallet on the loading space of the trucks without moving.”

The Beumer stretch hood A packaging system is able to package reliably up to 110 pallet stacks per hour with a stretch hood made of conventional films, having film strengths reaching between 40 and 150 micrometers. But what about thinner films or films which are more rigid, smoother or less elastic? These are the questions posed more and more by the owners of packaging systems since the new packaging law came into force at the beginning of 2019 changing a lot of things.

More recycling in Germany

When it comes to recycling, the multiple properties of plastic become a problem. In Germany, for example, more than 90% of all plastic waste is collected again, but only 43% of it is recycled and then reused. Well over half, 55% in total, end up in incineration plants and are used to generate electricity and heat or are processed into alternative fuels.

In order to change this, the manufacturers of consumer goods, building materials or furniture as well as the film producers have to change their way of thinking. Currently, most of the plastic is extracted as primary material from crude oil. In the future the parts of recycled plastic should perceptibly increase: this is what politicians and recycling companies in the European Union want.

“Our target is less plastic packaging and more recycling. To achieve this target we need all parties involved: manufacturers, trade and consumers,” says Federal environment minister Svenja Schulze. “With the new law, we in Germany will recycle considerably more than before.”

For example, the recycling rate for plastic packaging will increase from 36% to 58.5% and to 63% by 2022. This means that the owners of recycling systems must be able to prove that they recycle an appropriate part of the packaging they accept. The new packaging law is mainly intended to prevent waste and increase recycling.

Recycling is efficient

For the film manufacturers who supply Beumer Group, this is an economical solution to recycle their own production waste. The old material can be processed into regranulate and fed back into the production cycle. The utilisation of one’s own regranulates permits the manufacturer to conserve resources, reduce emissions, minimise waste by recycling and avoid environmental impacts. Ideally: their quality can be even compared to that of new material. “In this case, nothing changes for our packaging system,” emphasizes Spiekermann.

However, the film properties can considerably change due to the portion of recycled material. The Beumer sales manager mentions a film manufacturer, who relies simultaneously on high quality and less material. “The stretch films are therefore thinner but more efficient than conventional films,” he says. Thus, the packaged products are secured in optimum way and at the same time less material is used. The result is a higher production throughput and less exchange of film rolls at the machine.

Spiekermann: “We have thoroughly tested the film with our Beumer stretch hood A packaging system, which handles these thin films in a safe and reliable way.”

Together with the film manufacturers, the Beumer experts have performed tests and analyses with various films in their in-house R&D centre. “We have noticed that films with a high portion of recycled material behave like conventional plastic material during processing,” says Spiekermann.

Clean packaging as usual

So everything is clear? “Yes,” the Beumer expert is sure. “We welcome the new packaging law. After all, sustainability is part of our corporate philosophy.”

Thus, the users can continue to use the high-capacity packaging system to cover detergents, paint buckets, barrels or champagne boxes on pallets with a highly elastic stretch hood. The film fits very tightly, ‘like a second skin’, to the entire stack and thus, ensures the necessary stability even with the new films we tested,” Spiekermann describes.