Automation in logistics is no longer a distant dream. It is already a successful reality in a growing number of companies. How automated guided vehicles (AGVs) can effectively optimise warehouse logistics and what the path to an automated material flow can look like was presented digitally by STILL intralogistics experts on April 13th 2021 at Hannover Messe under the central topic of ‘Digital Transformation’.

The best-practice example of the Danish technology group Danfoss clearly shows how the automation of a production warehouse in Tinglev with STILL transport and software systems became a game-changer for the entire production logistics.

The advantages of automated logistics processes have been known for years. However, in the past few months their importance significantly increased. More urgently than ever, digitisation, flexibility, availability and smart, independent warehouse control are on the agenda of many companies. The good news is: “All the prerequisites are at hand – from technologies to investment models to experienced implementation partners,” explains Hubertus Wabnitz, STILL’s Head of Sales Automated Solutions.

Often, the last hurdle on the road to automated processes is the question “How do I tackle it?” Experts such as STILL, with a broad portfolio of AGVs, intelligent software applications, many years of expertise and a high level of professional consulting skills, are now in demand as partners to help companies on their way to efficient, optimised logistics processes.

STILL has been implementing customised automation solutions for customers for several years on the basis of comprehensive consulting. “Consulting is crucial in order to analyse the automation potential of the customer’s existing logistics together with the customer, to define a reasonable level of automation and to develop a technical basis for an automation concept,” explains Wabnitz.

Intelligent technology optimises logistics processes

Where AGVs ensure a smooth flow of materials, both among themselves and in an optimal interaction with manually operated vehicles, companies benefit in many ways. “Production capacities can be massively increased and reliably planned, regardless of the time of day or the lack of skilled workers. Costs can be optimised and ultimately reduced, due to their complete transparency of processes and reliability, among other things,” says Wabnitz.

In combination with a variety of acquisition and leasing options, automation projects thus become investments that quickly pay off for companies. The risk of transport damage and accidents decreases rapidly while employee safety and the quality of work are improved.

Automation as a success factor

One example of how automated transport systems can become a game changer and optimise entire production chains is the intralogistics project that STILL successfully implemented in Tinglev, Denmark. The aim of the Danfoss technology group was to increase capacity by merging different external warehouses with an automated storage system. Also, the warehouse should be set up flexibly for the requirements of the future. In addition to increasing capacity and scalability, time savings, space optimisation and process harmonisation were decisive goals.

After an extensive consultation and planning phase, STILL implemented a perfectly coordinated combination of six automated series industrial trucks (three MX-X order picking stacker trucks and three EXV high lift pallet trucks) at Danfoss, including all system components.

“In line with current production and material requirements, the warehouse was divided into a fully-automated area with narrow aisles and a semi-automated area with more space for manual order picking,” explains Wabnitz. “Peaks in orders can be responded to flexibly with an increase in vehicles.”

The Tinglev warehouse is a true benchmark project: Danfoss is currently building a modern distribution centre in Rødekro using the same technology by STILL. It is designed for the automated operation of twelve MX-X order picking stacker trucks and five EXV high lift pallet trucks.

Smart technologies for control, optimisation and safety

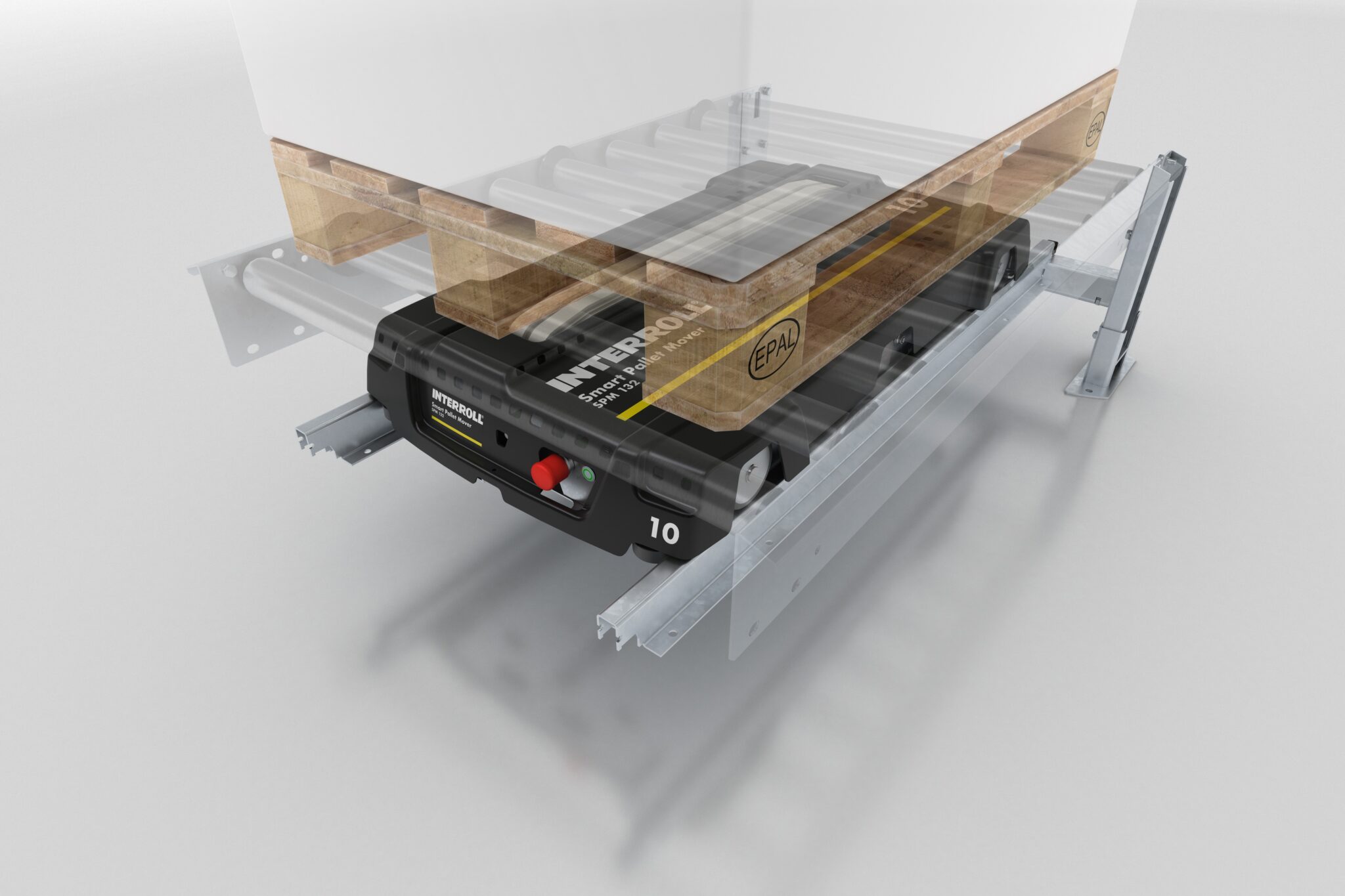

All AGVs are equipped with the so-called standardised iGo systems automation kit. A modular technology that is almost the same for all applications. The AGVs are manufactured in the same factories as the manual series vehicles. As most components are similar, it is possible to equip the series production vehicles with a so-called automation interface onto which the automation modules can be plugged.

In order for the trucks to be able to move independently throughout the warehouse area, various navigation technologies work together. With STILL iGo insights and the additionally integrated ELOshield safety system, driverless transport logistics at Danfoss is also equipped with two further innovative technologies. With iGo insights, STILL offers an AI-based tool that filters out correlations from the wealth of process information collected in the cloud so that specific recommendations for action can be derived.

This enables Danfoss to further optimise the availability and performance efficiency of the system. The intelligent tool uses the principle of machine learning to improve system performance. All data collected by the control system over a longer period of time is uploaded to the cloud for evaluation and can be accessed online at any time via the encrypted web portal.

The ELOshield system consists of several components that communicate with each other via radio and together form the all-in-one warning system. If an automated industrial truck encounters a pedestrian, the permanently installed module detects the approaching vehicle. A visual and acoustic signal is given. In case of danger, the truck is even slowed down. Each truck is automatically assigned a speed adjustment when entering and leaving the aisles. AGVs are not allowed to enter aisles where picking is taking place.

Shaping the future together

The customer is already very satisfied with the automated warehouse. “An initial analysis already showed cost savings of around 20%,” states Martin Jessen, Production Supervisor at the Danfoss warehouse in Tiglev.

In addition, considerable time savings have been achieved, with deliveries to production every three hours, five days a week. “With full service leasing, we also always keep an eye on the warehousing costs for the next six years,” he adds. Another project with STILL as automation partner is already being planned.