In modern warehouses, space is becoming increasingly limited. This creates a constant challenge: how to store more goods safely while ensuring fast, accurate retrieval. But when saving space comes at the cost of performance, efficiency often suffers. That’s why leading logistics operators are turning to smarter, quieter solutions that not only optimise space but also enhance overall performance.

Setting a new standard for Vertical Lift Modules

One recent Megadyne customer set a clear objective: to develop a next-generation vertical warehouse capable of reducing occupied space by up to 90%, while maintaining the same storage capacity. Additional goals included lowering energy consumption and improving both speed and reliability during goods retrieval.

With nearly seventy years of experience in storage and material handling systems, the customer, a company specialised in designing and constructing vertical automated warehouses, turned to Megadyne to help optimise operations. Already in the design phase of a new solution, the OEM sought to reduce the footprint of vertical storage modules while enhancing operational efficiency.

The problem: chain drive limitations

The customer’s previous solution used chain drives to move shelves, a system that came with significant drawbacks:

• Excessive noise

• Dirt accumulation

• Constant lubrication requirements

• Limited precision

• Slower operating speeds

• Frequent maintenance needs

These issues disrupted operations, reduced uptime, and created a noisy, less efficient environment – far from ideal in high-performance warehousing.

Solution: The QST system

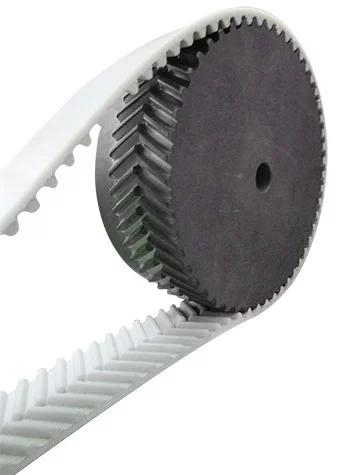

To overcome these limitations, the OEM partnered with Megadyne to implement the innovative QST (Quiet, Self-Tracking) System. A quiet, high-performance alternative to chains and standard straight-tooth profiles, the QST 14 M pitch is designed for heavy-duty applications requiring maximum torque transmission and durability, like warehouse automation.

The results were immediately evident: “This solution offered a significant reduction in noise levels, required less maintenance, and remained highly resistant to heavy loads. With high torque capacity and positive engagement in bi-directional movement, the QST technology provided the precision and speed necessary for optimal warehouse performance,” said a spokesperson.

Beyond boosting performance, this solution contributed to a quieter, cleaner, and more energy-efficient warehouse environment. What’s included in the QST System? The system includes belts, pulleys, and a clamp, all engineered to ensure optimal performance:

• Maximum compatibility

• Secure installation

• Minimal risk of operational errors

Download the full story: Delve into the full case study to explore how this high-performance solution set a new benchmark for vertical lift module systems.

similar news