In February 2021, logistics service provider Jenkins upgraded its warehouse management system (WMS) to ensure its business is future-proofed and continues to be at the leading edge of logistics solutions. Its requirements: fit for purpose, well-integrated to its other systems, and fully tailored to the needs of logistics service providers. it opted for 3PL Dynamics, enabling the logistics service provider to realise a major digitalisation improvement that will effortlessly respond to customer needs and demands.

For over 35 years, Jenkins has been one of the UK and Ireland’s market-leading providers of efficient and innovative port-centric warehousing and logistics solutions. It can design and implement flexible logistics solutions tailored to individual needs – giving unrivalled control of supply chain costs, with quality assured just-in-time delivery directly to customers nationwide.

Roughly 18 months ago, Jenkins decided to seek out a new WMS solution. In February 2021, it successfully went live at its site in Liverpool and is confident 3PL Dynamics is the right solution to roll out across all 10 of its sites.

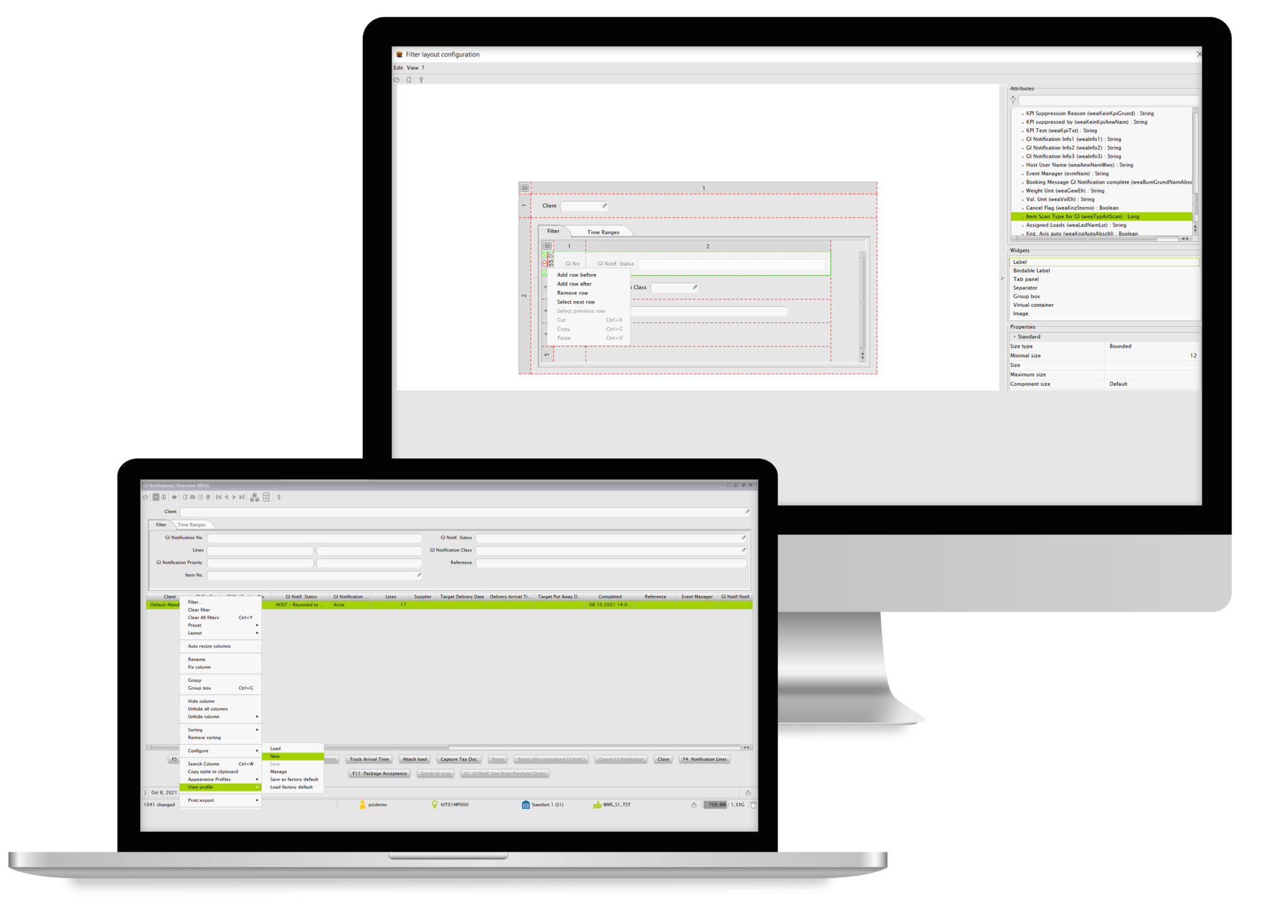

To ensure all its logistics processes run with maximum efficiency, Jenkins opted for the always up-to-date solution from Boltrics, developed with the input of more than 200 logistics service providers. Boltrics’ Warehouse Management System is specifically designed for logistics service providers, like Jenkins, to help streamline warehouse activities.

As well as warehouse management, 3PL Dynamics includes capabilities for freight management, transport management, and more. Mercurius IT is one of Boltrics’ international partners and the only UK provider for 3PL Dynamics. With over 16 years’ experience implementing business management systems, there was no doubt Mercurius IT was the right partner to complete this project. Its team worked closely with Jenkins to ensure the implementation was completed according to its timescale and business needs.

Paul Prenter, CFO at Jenkins, said: “The system will reduce many of the manual elements the legacy systems require, safeguarding against user error and allowing the individual to spend their time more valuably. This allows all users the opportunity to develop their skills and make use of their time and attention in the most productive way possible.

“Another great feature of the Boltrics system is its web portal, allowing our customers greater visibility of their stock than they have had previously. The web portal allows the customers to access their own version of the WMS and to take their own stock inventories, check on the status of their deliveries, and provides details on the status of stock expected to arrive. This provision enhances our customers’ ability to access and manage their stocks in real time, which helps them drive efficiency.”

Lee Williams, Jenkins Super User, added: “It’s a revolutionary system that will streamline our inputting, investigating, reporting and invoicing processes. It will really enhance our customer user experience whilst saving us time.”

With Phase 1 – successfully going live at its site in Liverpool – complete, Jenkins is confident to switch the other sites to 3PL Dynamics as well. With the help of DataHub EDI integration, Jenkins’ WMS and its customers’ systems will be integrated for exchanging information more efficiently.