Palletforce, a British specialist in express palletised freight distribution, has partnered with Clarus WMS to further enhance its logistics operations. This strategic collaboration demonstrates Palletforce’s commitment to cutting-edge technology and operational excellence, as it integrates Clarus WMS to automate traditionally manual tasks such as invoicing, while offering enhanced real-time visibility for both operations and customer deliveries.

Kate Lovatt, IT Director at Palletforce, commented on the partnership: “At Palletforce, we’ve always embraced technology to drive operational efficiencies. As a leader in express freight distribution, our SuperHub and live tracking systems are industry standards, and with Clarus WMS, we’re excited to push the boundaries even further. This partnership will bring valuable efficiencies, benefiting our operations and providing our customers with even better service.”

Leveraging Automation for Scalable Growth

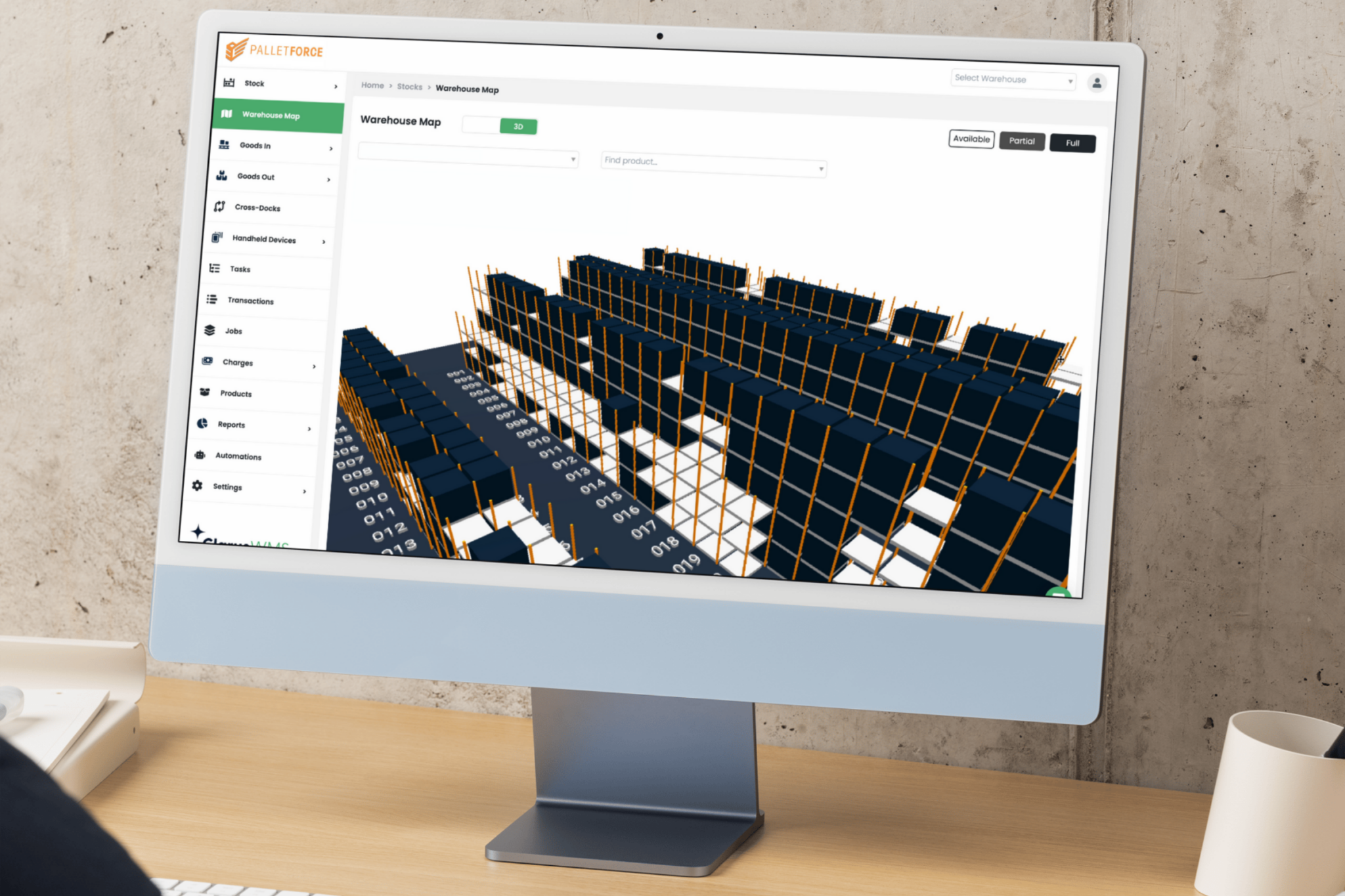

When Palletforce began exploring automation options, the objective was clear: to streamline operations by reducing manual tasks, enabling the company to scale efficiently without compromising service quality. After a thorough evaluation of available solutions, Clarus WMS was chosen for its innovative capabilities and its ability to seamlessly integrate with Palletforce’s existing infrastructure.

Lovatt added: “We’ve always been leaders in adopting new technology. When we reviewed other WMS solutions, Clarus WMS stood out in terms of flexibility and innovation. This partnership will not only improve our internal processes but also unlock new possibilities for our customers.”

Driving Continuous Improvement

Since the start of the partnership, Palletforce has seen immediate benefits, including the automation of invoicing, which has reduced administrative time and improved accuracy. Customers are also benefiting from real-time tracking and updates, which provide full visibility throughout the delivery process. As the company continues to embrace automation, the Clarus WMS solution is enabling more scalable workflows that support the company’s long-term growth plans. The partnership marks a key milestone in Palletforce’s ongoing drive to transform the freight experience and provide enhanced value to its customers.

Glen Wilkinson, Head of Sales at Clarus WMS, said: “We’re excited to be working with Palletforce to raise the bar in logistics. This partnership represents a significant step forward in creating a faster, smarter, and more flexible freight experience for both Palletforce and its customers.”

With a shared commitment to continuous improvement, both companies are looking to the future, with plans for further collaboration to drive innovation and success in the logistics sector.

similar news