Nationwide Platforms recently provided working at height support to Yusen Logistics (UK) for the set up of their new site, located at Pannatoni Park, just off Junction 16 of the M1, near Northampton, England.

Yusen Logistics (UK), which is a division of Yusen Logistics Co. Ltd, is a leading provider of logistics solutions with over 2.96 million sq. metres of warehousing space. It employs over 25,000 people worldwide at more than 680 locations across 47 countries and regions. The company is a diversified global market leader in logistics. This project marks the first official use of a hydraulic-oil-free electric scissor lift in the UK, the Dingli 1612PA 15.7m scissor, which has been leased on a permanent-hire basis. Yusen Logistics also used one of Nationwide Platforms’ brand new Dingli 1912DC 19m electric scissor lifts.

The challenge

The first challenge was that the project required frequent stock-counts of products stored in racking. Bringing each pallet down to the ground for counting and then returning it to its original place would have taken around five minutes per pallet, which in a warehouse of this size would be time-consuming. Furthermore, manoeuvring stock from the racks to the ground would have required heavier machinery taking up far more ground space.

An additional challenge was that setting up the warehouse required the installation of porta-cabins which came equipped with in-built lighting and heating systems. However, these systems still needed to be connected to power outlets and data banks located at high points within the warehouse, making it hard to connect the cables into the porta-cabins at ground level.

The solution & benefits

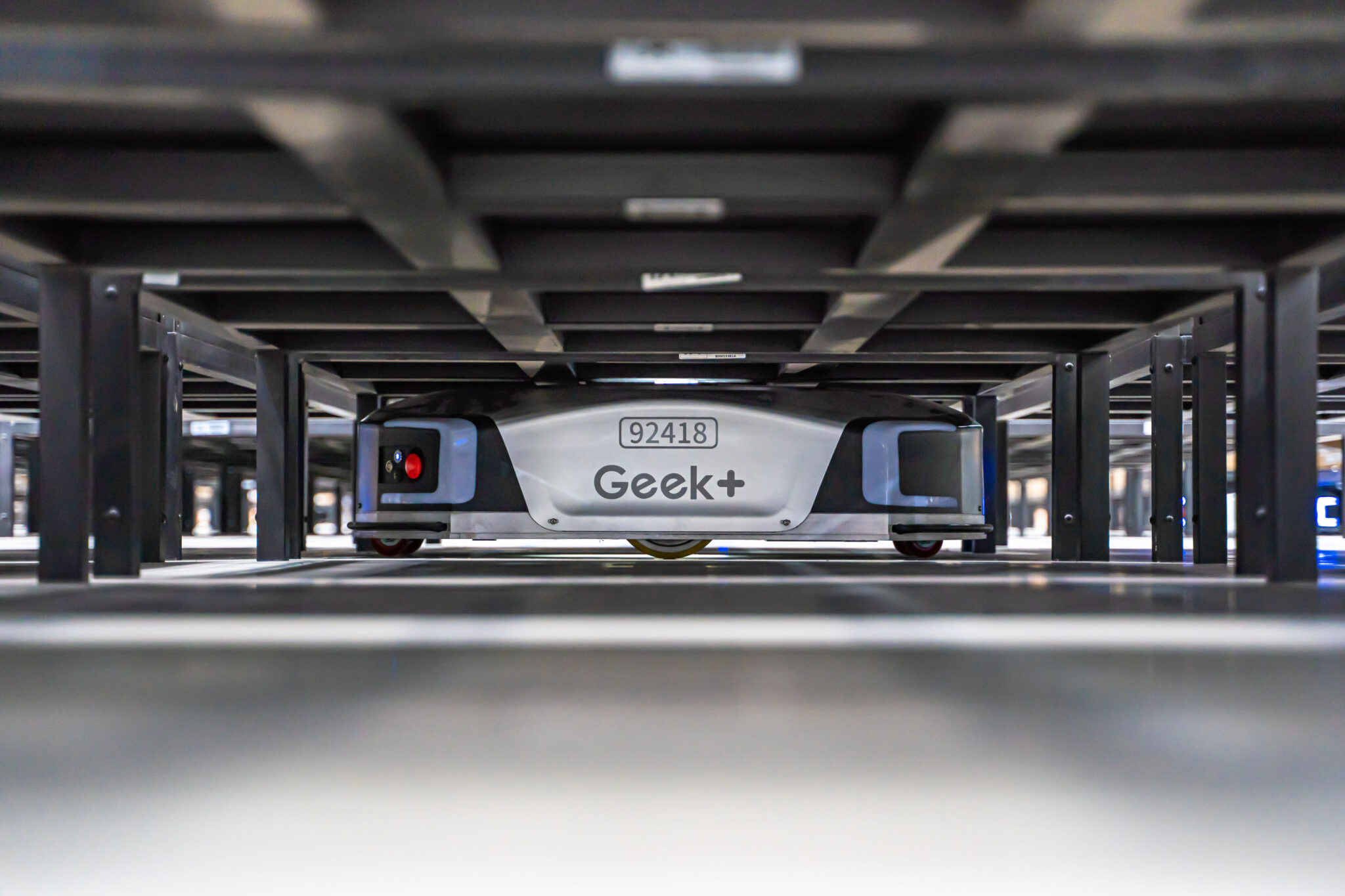

Nationwide Platforms surveyed the site to determine the best machine for the project. Because this was an indoor project with multiple personnel present, non-polluting machines with high safety credentials and non-marking tyres were required. In addition, since the purpose of the warehouse was to maximise the use of space for product storage, the machines needed to be lightweight enough and agile enough to manoeuvre between aisles of stock.

What this called for was a very unique and brand new piece of equipment: the Dingli 1612PA 15.7m hydraulic-oil-free electric scissor lift. One of the only hydraulic-oil-free machines of its kind, and the first one to be used in the UK, this machine provided a distinct operational advantage.

Most importantly, because the scissor lift was hydraulic-oil-free, the risk of troublesome oil spills was completely eliminated. Oil spills can prove detrimental to a project, since they can negatively impact not only the quality of stock, but also site safety and sustainability compliance. An electric machine, the Dingli 15.7m does not emit harmful pollutants and has low working-noise levels, which means it was also perfectly adapted to an indoor environment frequented by multiple operators and other personnel.

To enhance the machine’s safety profile even further, handrail lagging was fitted to the machine basket to avoid accidents and provide an added degree of protection when working next to high-value assets in the warehouse. Supplementing this were NoNoc bumper doughnuts fitted to the basket’s rail edges, which would prevent the scissor from potentially damaging the stock by providing a buffer before contact was made.

For stock counts, personnel would use the narrow and lightweight Dingli 15.7m scissor lift to navigate the corridors of floorspace between the racking aisles. Rather than engaging in the time-consuming task of moving stock to ground level, operators would ascend in the MEWP to take a stock count of the highest pallets. When positioned effectively, the scissor platform enabled multiple pallets to be counted from the same position by a single operator for maximum efficiency. Using a scissor lift enabled operators to count 25 pallets in five minutes, which is the time it would otherwise have taken them to lower and return a single pallet.

There was no need for oil changes or fuel maintenance, which further reduced downtime and thereby improved the machine and overall project’s efficiency. Another Nationwide Platforms machine was also on site: the brand new Dingli 1912DC 19m electric scissor lift, whose extended reach proved essential in connecting up the power within the warehouse.

The data and power cabinets were located two thirds of the way up the stanchions, making them unreachable by ordinary personnel. Using the Dingli 19m scissor lift, contractors took the power cables up in the lift and fed them through rafters on the roof, before lowering them into the porta-cabins and connecting them from above. This ensured there were no cables at ground-level causing safety hazards.

Pat Rose, Interim Site Manager at Yusen Logistics, said: “The Dingli 1612PA has proved unparalleled for work in an indoor warehouse environment, especially one with space restrictions such as a storage facility like this one. It’s significantly maximised our productivity, and it has enabled us to keep on top of our inventory without having to rely on extra manpower or a rearrangement of our entire stock. Sustainability is a core strategy for Yusen Logistics, so being the first in the UK to utilise this unique machine is a great privilege. Hydraulic-oil-free machines come with numerous environmental and safety benefits, and we’re delighted to have been able to see them in action.”

Matthew Parfitt, Head of Market Development – Warehousing & Distribution at Nationwide Platforms, added: “This is a UK-first and we’re very excited to see such an innovative machine put to use in the warehousing and facilities sector. Our fleet is equipped with numerous machines tailored to a variety of indoor requirements, and the Dingli 1612PA is one of our newest additions. This machine and this application offers a blueprint for future long term warehouse scissor applications where productivity is maximised and sustainability maintained. We look forward to more companies taking advantage of the obvious benefits of a machine without hydraulic oil and look forward to working with Yusen Logistics again in the future.”

similar news

Hörmann Transdek launch range of Scissor Lifts