Basement parking is an attractive proposition, especially in congested urban environments. But it has always come with headaches. Access ramps take up a lot of space, both outside the building and in the parking area itself. And they are expensive to install. Lift specialist Hymo, part of VPG, now has a solution that cuts capital expenditure and increases rental and sales income – and could transfer to logistics uses.

Use a lift, not a ramp

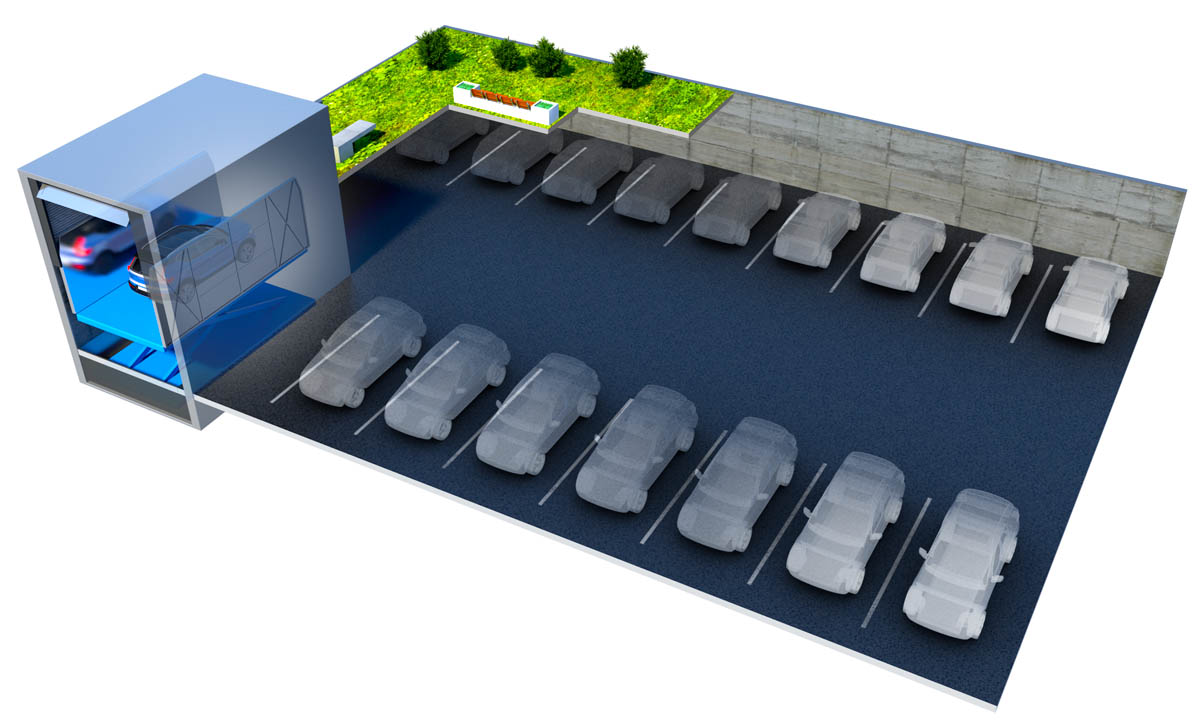

Traditionally, drivers have accessed basement parking via awkward ramps that are still the norm in cities. But ramps are expensive to construct. And they occupy a lot of valuable space, not only at ground level but also in the basement parking area itself. The way ahead lies in automated parking systems based on lifts.

“These systems are the architect’s dream solution,” observes Rutger Clovén, Business Development Manager at VPG. The space around the building is freed up for people, play, and plants – a green bonus that satisfies both city planners and environmentalists. Meanwhile, the architect has more space to play with in the basement, which now offers more parking spaces and/or more usable space for facilities.

Startling financial benefits

“We’ve crunched the numbers for lift-based systems, and the financial benefits really are startling,” says Rutger. “A single parking space adds about €50k to the value of a property, or approaching €2k a year in rental income. But using a lift-based system can increase the number of spaces from, say, 11 to 17 for a typical apartment block.”

That makes it possible to add two extra floors of apartments on the same building plan, which enables developers to make much more of their property. “In hard cash, it all adds up to gains of hundreds of thousands of euros,” Rutger points out.

The way ahead

“Automated lift-based underground parking is the way ahead,” says Rutger. “Many architects are still sticking to the familiar ramps, but those with a forward-looking, greener, mindset are keenly interested in the new way.”

“We have been manufacturing scissor lifts for these applications for years, with hundreds of systems installed,” notes Rutger. The big advantages are their ease of operation, which residents value, plus the outstanding reliability and security that property owners demand. “But we are now going further, by developing a new concept for a total solution for smart parking. We’ll be piloting it in Germany later this year – watch this space for more news as it happens!” concludes Rutger.