While Witron Logistik + Informatik GmbH celebrates its 50th anniversary this year, its UK subsidiary is also celebrating its 25th company anniversary. Founded in July 1996, the site in Stoke-on-Trent has developed from a one-person sales office into a strong team with now almost 70 employees who secure deals with new customers and serve existing customers in the UK. The subsidiary is continuously growing and is seeking many new specialists.

“It all started with a project for Universal Office Supplies”, says Jack Kuypers, Witron Senior Vice President North West Europe. “Additional cross-industry customers such as Pirelli Tyres, the Princes Group, Computacenter, Woolworth, Northern Foods, and Cepac followed soon.

“We also implemented several automated or manual logistics systems for customers such as food retailer Sainsbury’s, Bosch Siemens Hausgeräte, Tetrapak, and corrugated cardboard manufacturer DS Smith.”

For more than four years, Duncan Pointon has been responsible for the sale of automated logistics and picking systems as well as the customer support in the UK. “While the general contractor for logistics Witron was initially responsible for the design and implementation of the projects exclusively, the service portfolio has been successively expanded over the years.

“Thus, for customers such as the automotive parts distributor FEBI, the health and beauty retailer Boots, and the food retailer TJ Morris, in addition to the holistic material flow design, all IT and control components, as well as the conveyor system, the ramp-up, and individual remote and OnSite service models optimally tailored to the customers’ needs, were delivered by Witron”, explains the experienced engineer.

“Our cost-efficient, flexible, and ergonomic omni-channel solutions now have a unique selling point in the logistics world. Moreover, our customers – and we are particularly proud of this – rely on the values and culture that make Witron so unique: Rolling up one’s sleeves, keeping promises, being reliable and predictable, staying down to earth”, says Pointon, highlighting the strengths of the internationally operating family company.

Case and piece picking solutions

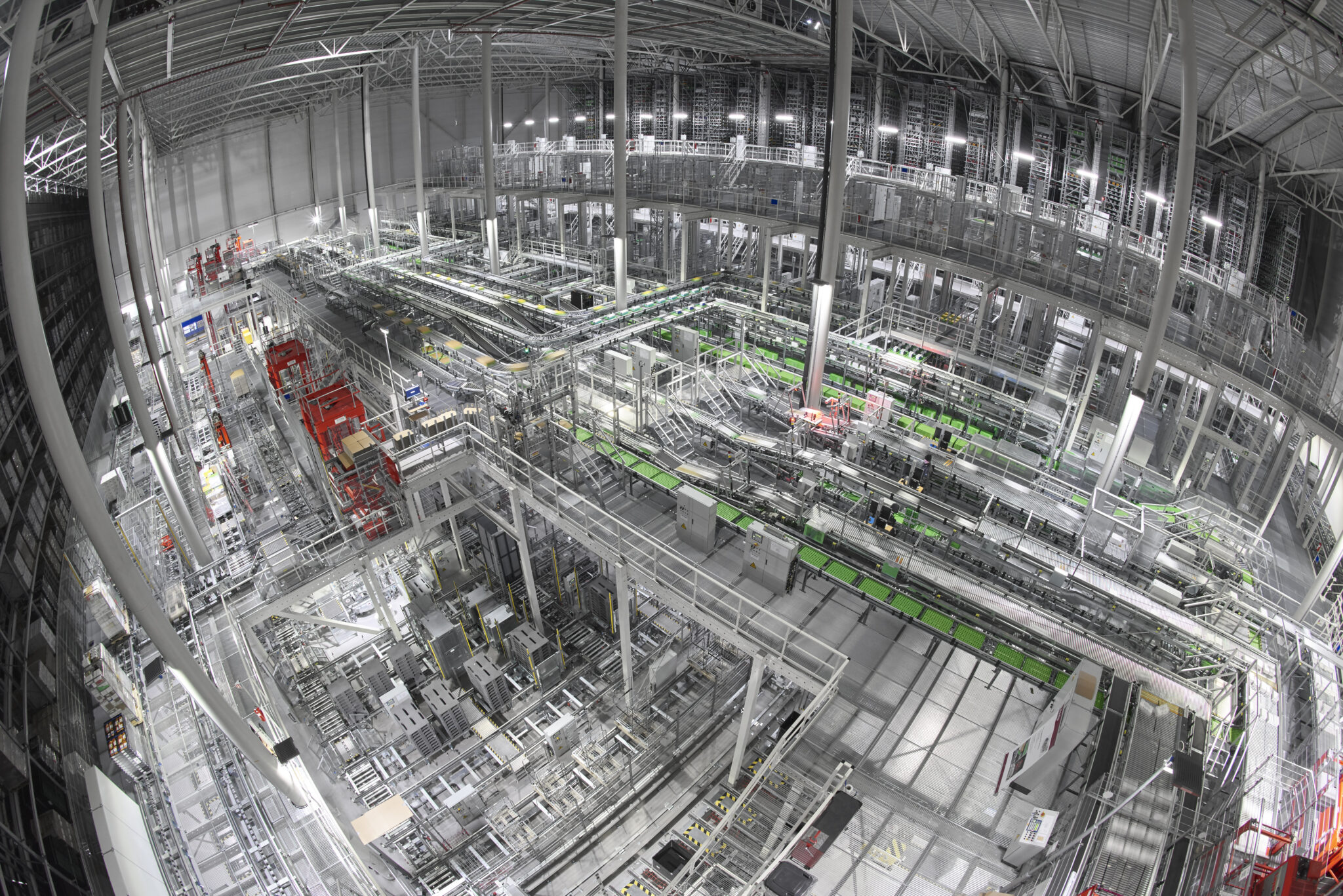

Witron considers itself as one of the pioneers in the UK, especially in food retail logistics and in the drugstore sector. For example, the two Sainsbury’s sites in Hoddesdon and Stoke-on-Trent continue to operate in a highly available, efficient, economical, and ergonomic manner even after more than 20 years of operation.

The Boots Store Service Centre (SSC) in Nottingham – in operation since 2007 – is one of the most dynamic logistics facilities in Europe and supplies more than 2,300 stores. On a peak day, almost 3 million pick units are picked there. The Covid-19 pandemic in particular demonstrated the enormous flexibility of the integrated Witron systems, which were modified from a pure store delivery process to a highly efficient omni-channel system within a very short time, and the warehouse now also supports Boots’ home shopping business.

In 2024, Witron will commission a new logistics centre for TJ Morris, the retailer headquartered in Liverpool. Its new client is one of the fastest-growing and best-rated UK retailers throughout Europe. While the family business currently operates around 550 shops under the “Home Bargains” brand, it is expected to be close to 1,000 in just a few years as a new store is added almost every week.

TJ Morris distributes a wide range of food, household goods, and general merchandise products. The mechanised system is designed for a daily picking capacity of 646,000 cases.

“Retailers in the UK are eager to learn about our intelligent omni-channel solutions such as the Order Picking Machinery (OPM) palletising robotics solution or the All-in-One Order Fulfilment System (AIO),“ Duncan Pointon announces.

“In the future, retailers in the UK will have to cope with a wide variety of challenges such as the availability of logistics staff, increasing cost pressure and higher logistics demands in a heterogeneous omni-channel environment. Witron’s solutions perfectly fulfil these tasks. They have been successfully implemented and utilized by market-leading retailers worldwide.”

Maximum delivery performance

High business demand, as well as the permanently growing service business, are reasons why the current office space in Stoke-on-Trent is no longer sufficient and requires a relocation within the city. That is why this year, the company will move into a state-of-the-art office on the premises of the renowned Keely University.

The move is being organised by Craig Goulding who has been working for Witron as a service and maintenance expert for almost 20 years. “Our customers can concentrate on their core business and we ensure continuously high availability of all software and mechanical components with our service teams based on a wide range of services. Thus, the logistics centres can supply many thousands of customers with goods via stores, repair departments, or online stores largely error-free every day.”

Colleagues wanted

Due to the high number of projects that Witron currently has in the sales pipeline in the UK, the company naturally requires a lot of new skilled workers. Well-trained craftspeople – electricians, mechatronics engineers, or metalworkers, as well as programmers and engineers from various specialised areas.

“And where is the best place to find them? – Right on the University campus”, says Craig Goulding. In addition to an interest in working with innovative technology and ongoing training, the ability to work in a team is a key factor. “We need team players, not lone wolves,” soccer fan Goulding sums up. “We are looking for colleagues who make the customers’ challenges their personal challenge – and are eager to solve it.”

In addition to a wide-ranging work environment in a crisis-proof and leading-edge industry, Witron is equally convincing with state-of-the-art workstations, an attractive salary, and a wide range of social benefits.

Looking ahead

A lot has happened at Witron in recent years – not only in the UK but worldwide. The Witron group is continuously growing. While Witron currently employs some 4,500 people and shows an annual revenue of €710m. Soon it will employ over 7,000 employees and sales will exceed the €1bn mark.

A new 120,000 sq m production facility for conveyor system components and control cabinets is currently put into operation at the company’s headquarters in Parkstein, a €200m investment which will more than double the company’s floor space.

“That’s why we are not only proud to look back,” Duncan Pointon and Craig Goulding agree, “but are also proud to look to the next 25 successful years. And as an attractive employer facing high demand for Witron solutions, we are sure that we can look forward to many future successes with numerous new customers and many new colleagues.”