The new “connect:charger” module as part of Linde Material Handling’s (MH) fleet management solution makes the charging processes of battery-powered industrial trucks transparent and reduces electricity costs while maintaining consistent, high vehicle availability through prioritization, defined charging time slots and power limits. Suitable for use across industries, the quick-to-install software and hardware solution proves its worth even with small fleets and will be launched in time for the LogiMAT trade show.

“Peak demands in energy are among the main causes of skyrocketing costs when it comes to operating electric industrial trucks,” says Stefan Roth, Product Manager Energy Systems at Linde Material Handling. Operators of forklift trucks and warehouse equipment powered by lithium-ion batteries are especially likely to experience this because part of the concept with these applications is to charge the batteries regularly during the day in order to continuously extend their runtime. However, if too many employees connect their electric vehicles to the chargers at the same time, for example during breaks or after the end of the work shift, the power demand increases rapidly. In the case of lithium-ion batteries, this is compounded by the fact that fast charging is associated with significantly higher power demand than with the lead-acid variant.

“As the number of consumers increases, so does the risk that peaks in power consumption will occur,” Roth points out. “These short-term peaks can lead to permanent cost increases if the electricity tariff is linked to compliance with certain limit values,” he adds. But even if there are no limit values involved, with larger fleets it can be difficult to decide when to charge which vehicles in order to ensure their availability or to move charging to daytimes when electricity rates are cheaper. “All these requirements can be handled quickly and easily when using our digital charge management system, connect:charger,” explains Stefan Roth.

Intelligent charging

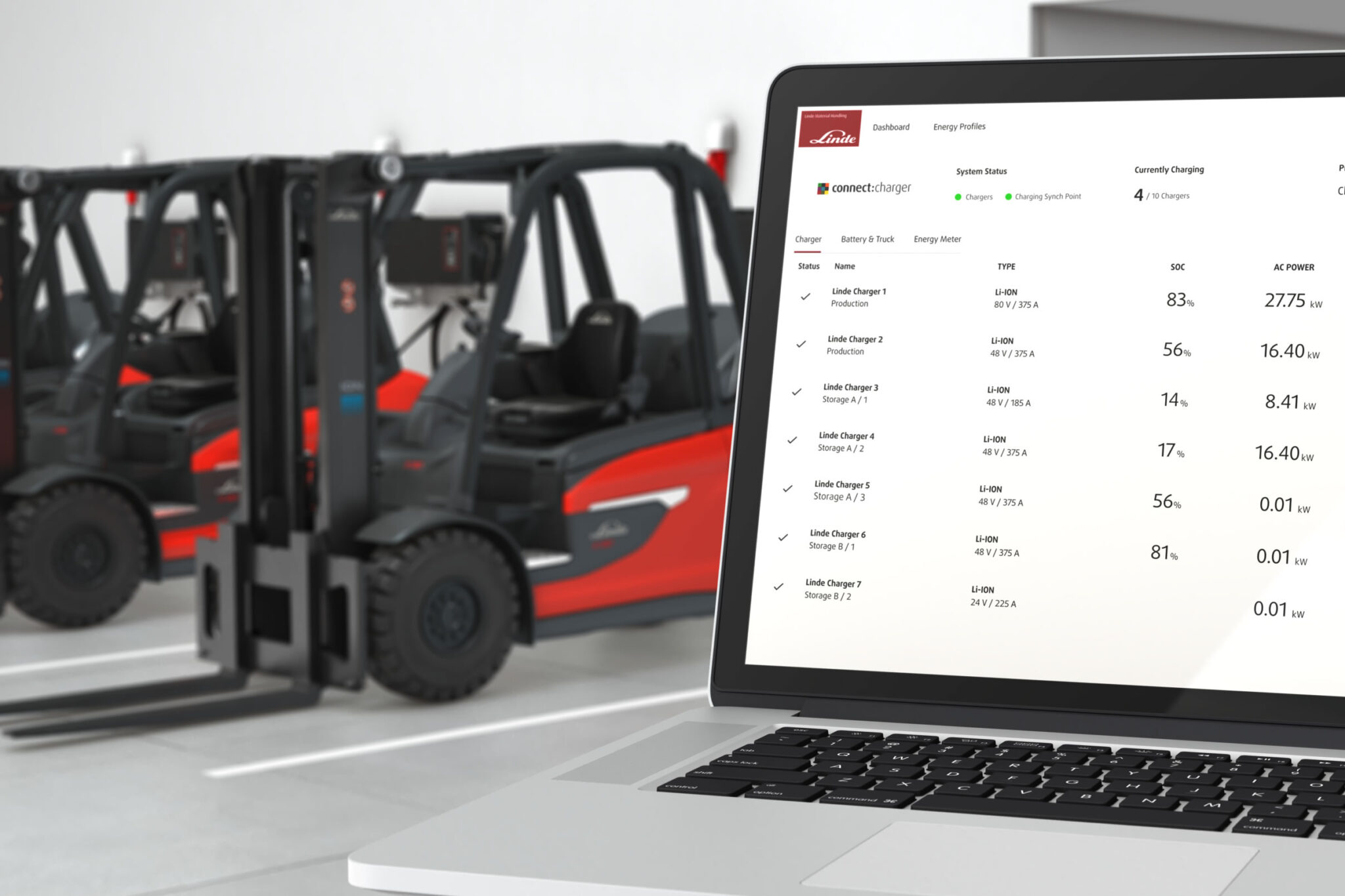

To do this, the new Linde system links up to 50 chargers in a network with a central hardware unit, which automatically controls the power demand according to predefined rules. Additionally, a dashboard allows forklift drivers and fleet operators to retrieve all the relevant information. For example, they can see when a particular industrial truck is ready for use again or how much energy the individual chargers have consumed over the course of the day. The dashboard also allows settings to be made with just a few clicks to adapt the charging behaviour to operational requirements. “Fixed charging times or maximum power levels can be defined. It is also possible for fleet operators to give individual chargers priority over others, for example, if a vehicle’s battery charge is below 50 percent,” explains product expert Roth. The intelligent charge management algorithm coordinates the various specifications and allocates appropriate capacities to the chargers.

There are two options as regards data transmission from the chargers to the control unit: Initially available at the market launch will be the wired solution (for up to 50 chargers). However, a wireless version will also be on offer shortly. Furthermore, there are plans to integrate additional software functions ranging from dynamic charge management and a cloud-based application to the integration of the charge management solution into a holistic energy management solution. The Linde connect:charger module can also be retrofitted, provided the charging devices feature an integrated interface (from year of manufacture 2018).