Unitechnik Systems GmbH will be presenting UniWare-AI, the AI-based assistant for logistics systems, at LogiMAT 2024. The AI tool will support the system integrator’s customers in predicting order loads and bottlenecks in the material flow, for example. Visitors to the trade fair can find out more about the project, which was developed in collaboration with the Technical University of Cologne, at Stand H20 in Hall 1.

The new feature of the UniWare warehouse management system provides warehouse managers with an intelligent assistant. Based on data from the logistics software, the AI tool provides recommendations and insights. For example, it can predict how many order items will need to be processed over the next few days. Using data from the logistics system, the AI assistant can suggest the best way to place items in the warehouse or analyse the causes of breakdowns to make predictive maintenance recommendations. The more data the system receives over time, the more the AI model learns – the learning logistics centre becomes a reality.

Better AI model thanks to external data

The predictive quality of UniWare AI can be significantly improved by incorporating external data from other customer systems. For example, historical order data from the ERP system or data on seasonal characteristics or weather data from external sources can be integrated. Unitechnik’s experts create these data models individually for each user. Together with the customer, they optimise the use of UniWare-AI step by step. UniWare-AI is already being tested at DEHN SE to optimise personnel scheduling. Using the data from the AI model, the electrical engineering company can predict with a high degree of probability the workload for order picking over the next few days. The pilot project was developed in collaboration with the Faculty of Computer Science and Engineering at the Technical University of Cologne.

LogiMAT motto: Logistics in time

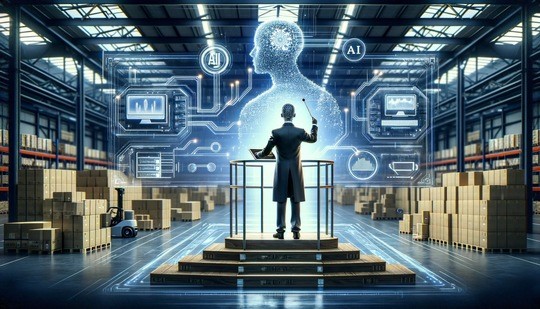

For Unitechnik, the motto of this year’s LogiMAT is “Logistics in rhythm: warehouse management system with AI power”. As the conductor of the (warehouse) orchestra, the UniWare warehouse management system coordinates the customer’s increasingly diverse system components. In addition to traditional warehouse and conveyor technology components, soloists (autonomous subsystems) such as AMR or AGV systems are increasingly becoming part of the orchestra. UniWare is the (artificial) brain of the logistics centre. It ensures the harmonious interaction of the players and, with its AI power, constant optimisation.