The logistics industry is pumping a massive £185 billion into the UK economy each year and providing jobs for around 8% of the workforce. That’s over 214,000 companies working tirelessly to keep goods moving across the country and the globe. With trade volumes surpassing £1 trillion annually, the sector is the backbone of our economy.

Unsurprisingly, this growth, coupled with last year’s Electronic Trade Documents Act (ETDA), is driving a tech transformation in logistics, with companies increasingly turning to automation and IoT (Internet of Things) to keep up with demands.

How IoT is transforming logistics:

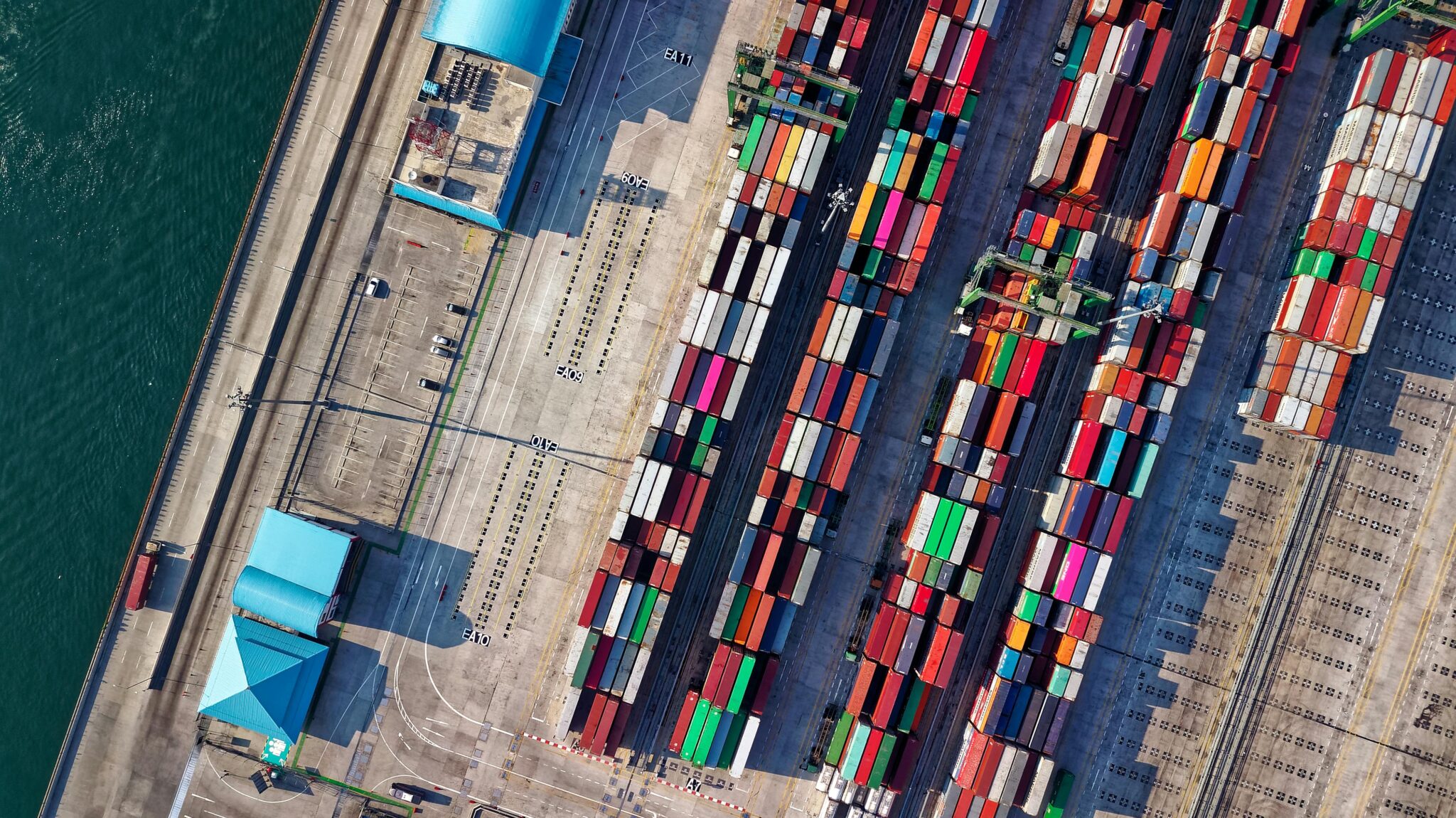

1. Real-time tracking and visibility: With IoT sensors on vehicles, containers, and packages, logistics teams can monitor every step of the journey, from location to temperature, ensuring compliance and safeguarding sensitive goods like pharmaceuticals.

2. Smooth inventory management: Automated tracking through IoT sensors reduces manual errors, while cloud platforms enable instant access to inventory status, improving forecasting and reducing costs.

3. Predictive maintenance: IoT sensors monitor equipment health, predicting maintenance needs before breakdowns, which keeps vehicles on the road longer and reduces unexpected disruptions.

4. Optimised route planning: Cloud-based route planning backed by IoT data helps avoid traffic, save fuel, and cut down emissions — making deliveries faster, cheaper, and greener.

![]()

5. Enhanced demand forecasting: IoT and cloud analytics allow companies to predict demand spikes, keep shelves stocked just right, and spot new market trends in real time.

6. Streamlined collaboration: Cloud platforms improve communication across the supply chain, with real-time data sharing between suppliers, distributors, and retailers, keeping everything in sync.

7. Boosted customer experience: Real-time tracking and personalised offers create a smooth and tailored experience for customers, fostering loyalty and satisfaction.

8. Upgraded security: With advanced cloud security and IoT-enabled monitoring, logistics companies can protect their assets and data, reducing risks of theft and cyber threats.

David Ritchie, co-founder of Propel Tech, which specialises in bespoke software for supply chain companies, says, “The Internet of Things (IoT) is revolutionising logistics, enabling businesses to achieve greater efficiency and prioritise customer needs. Success lies in the synergy of smart technology and custom software. Tailored solutions that seamlessly integrate IoT and cloud platforms, empower real-time, data-driven decision-making and optimise operations for each unique business.”

similar news

Complete Connectivity Within Reach for Logistics Industry, says IoT Provider