Part of the Meijer Group, Meijer Handling Solutions has just celebrated its 100th birthday. It’s been a century of innovation, and with another set to follow, the urge to innovate is far from over.

Meijer Group started as a one-man business in 1921, founded by Jan Meijer in the Frisian village of Wier, the Netherlands. Like many businesses at that time, Meijer focused on local agriculture. Jan went from farm to farm offering his services as a thresher. His son, Hendrik, took the first technical steps and expanded the range to include tractors and tracked vehicles. Under his leadership, Meijer grew to become a contracting and earthmoving company, carrying out repairs and developing new machines and machine parts. The company demonstrated technical and customer-specific thinking that soon bore fruit.

Hendrik’s son, Sjoerd, added his own contribution. Sjoerd was even more of a techie than his father and shifted the company’s course towards mechanical engineering and construction. Meijer proved himself by developing surprising and effective solutions to complex technical problems. The knowledge and experience gained from these activities were also essential to the development of the company’s present achievements.

These days, the fourth generation is at the helm in the person of Hendrik Meijer (pictured). Meijer Handling Solutions specialises in the production of logistics solutions, such as attachment equipment for material handling equipment and standalone systems. Apart from a brief excursion to Wieringerwerf, the company has always remained in Friesland. In St. Jacobiparochie, the Meijer Group employs approximately 170 people, but it still exudes the feel of a true family business.

Innovative solutions

The origin of current activities lies in the patented telescopic fork that was introduced in 1980, an innovation of Hendrik’s father. The hydraulic ReachForks concept was originally sold exclusively to KOOI, a manufacturer of portable forklift trucks, which at the time was sold under the name KOOI-AAP. In 2000, however, Meijer took over the sales and marketing rights. The official brand name KOOI®ReachForks was also acquired.

“That acquisition has been a success for us,” says Hendrik Meijer. “From then on, we could also supply our products to other OEMs of portable forklift trucks and distributors worldwide. During that time, we grew a department into a professional market leader.” In ten years’, the number of distributors rose sharply: from eight in 2000 to approximately 25 in 2010. Meijer Handling Solutions grew to become the world market leader in the production of hydraulic forks.

In addition to acquiring the sales rights, Meijer also invested in engineering. New innovative products were introduced, such as KOOI®RollerForks. “But we do more than just forks,” Hendrik Meijer continues enthusiastically. “We develop and produce pallet transfer systems for moving goods from one pallet to another, mast height extension and much more.”

Making products smarter

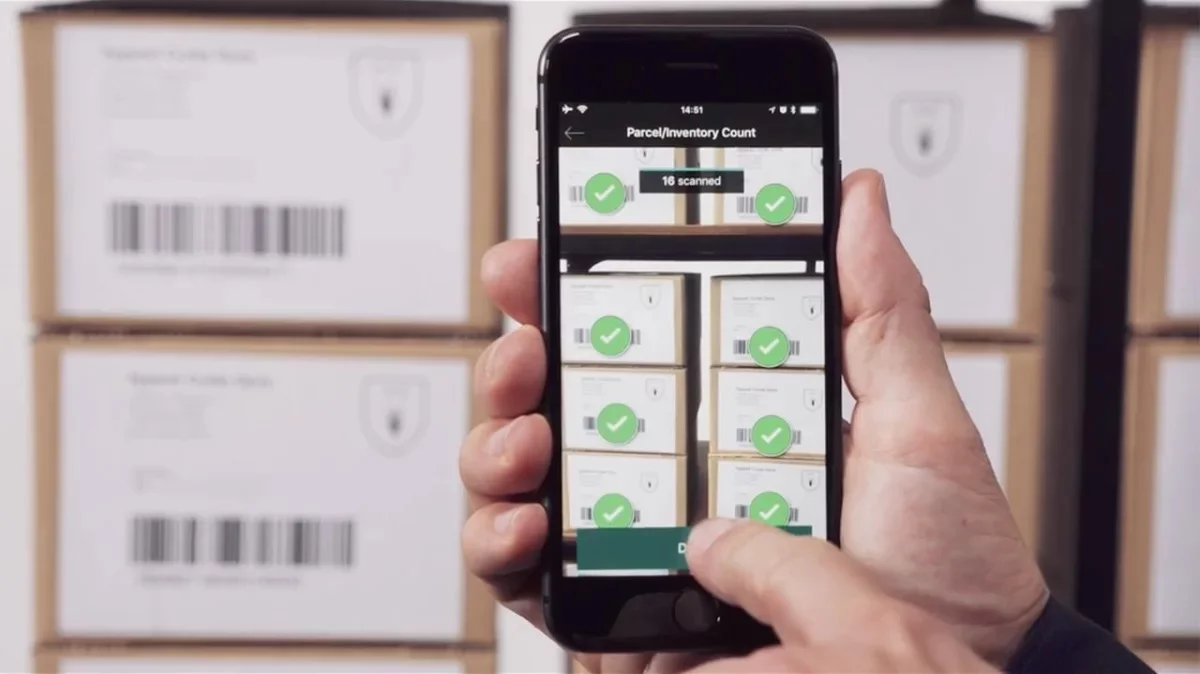

Personified by the CEO, Meijer Handling Solutions is still full of energy and innovation after 100 years. Today, the focus is on making products smarter. The KOOI® Next programme enables forklift trucks to be used even more efficiently. Handling speed can be increased, damage to goods, pallets and racks can be reduced and workplace safety can be improved. The KOOI® Next program is an excellent tool for providing users with essential information. Using an app on the mobile phone, for example, the deflection of the fork can be analysed. KOOI®ReachControl, a length measuring system for all kind of ReachForks, ensures that the extension of the fork stops at the right moment and the forks do not protrude too far through the pallet.

With the length measuring system, Meijer Handling Solutions also responds to the ongoing electrification of internal transport. “For example, we are developing an electric ReachFork,” says Hendrik Meijer. “To guarantee the quality that the market has come to expect from us, we are currently developing and testing various prototypes.”

“There are still many good things in store for the company,” says Hendrik Meijer. “We are a global market leader and want to grow in North America in particular. We have had a joint venture (Cascade-KOOI®) with Cascade there since 2019. Cascade is well represented in North America and our products fit well with their current programme.”

Locally made

Meanwhile, the production facility in St. Jacobiparochie does not offer sufficient space for this further global growth. “When the time is right, we will also look at manufacturing opportunities in other parts of the world. By manufacturing locally, we can also reduce transport and in turn contribute to achieving an environmentally friendly chain.”