Companies aiming to improve their competitiveness through more highly automated intralogistics will find everything they need from a single source at Linde Material Handling (MH): a broad portfolio of automated guided vehicles (AGVs) and mobile robots (AMRs), suitable for projects ranging from small to large and simple to complex. Additionally, they will have at their disposal a team of experts that has grown considerably in recent years and serves to ensure professional planning and implementation. With the Linde L-MATIC HD k automated pallet stacker, the company is launching an additional model with a lift height of up to 3.8 meters for the substantial field of horizontal transportation. The series truck offers corresponding delivery times, faster commissioning thanks to new software and simplified service. Furthermore, the near-series concept study of the Linde L-MATIC C automatic compact stacker will make its debut at the Linde MH booth at LogiMAT 2024 as part of an engaging live case presentation. Thanks to its compact dimensions, this truck featuring an integrated lithium-ion battery is particularly suitable for applications in confined spaces and for small and large vehicle fleets. It is scheduled to go on sale at the end of the year.

“The automation of material flow processes is now possible in almost all warehouse and production areas,” says Louis Vieira, Head of Sales Automation & Intralogistics Germany at Linde Material Handling, encouraging all logistics managers to get to grips with the subject. In his opinion, processes with a high degree of standardization are especially suited for this purpose. These include, for example, the low-level transport of goods between defined transfer stations, for which AMRs with transport platforms are recommended. The same applies to replenishment in high-bay warehouses using automated reach trucks or the picking of pallets in racks up to 16 meters high. “However, the largest range of applications for autonomous or automated industrial trucks is unquestionably found in the extremely versatile pallet stackers,” says Louis Vieira. The vehicles can be used for distance transport and are also capable of lifting loads to medium heights. They can be used for tasks ranging from production supply and the collection of finished products to transport between incoming goods and staging areas, the supply of goods for shipping and the transfer of load at the interface with VNA forklifts.

New models for a growing variety of applications

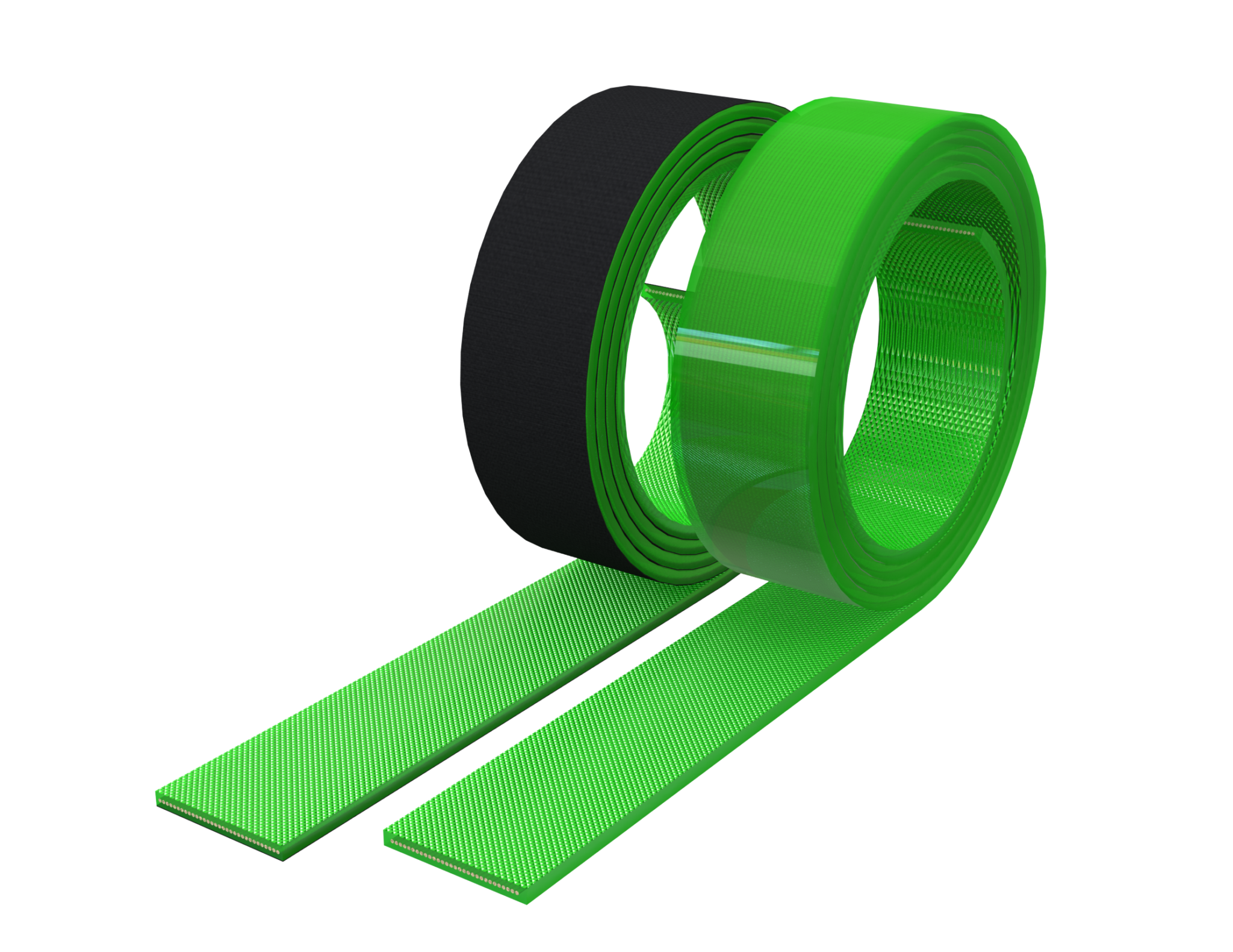

With the Linde L-MATIC HD k, another truck model for these and other applications is now being launched on the market. The automated pallet stacker can move goods weighing up to 1.6 tons between conveyor belts, frames, marked floor areas or rack locations and store and retrieve them at heights of up to 3.8 meters. The industrial truck features a range of 360° safety scanners and load sensors and can travel at speeds of up to 7.2 km/h. It already meets the technical safety requirements of the European ISO 3691-4 standard for driverless industrial trucks. The pallet stacker can be optionally equipped with features such as the Linde BlueSpot, warning lights, a second load sensor and additional obstacle detection. The Linde L-MATIC HD k draws its energy from either a lead-acid or lithium-ion battery; suitable chargers are supplied ex works, as is the truck itself. Various options are available for (intermediate) charging, both manually and fully automatic. In the latter case, the vehicle automatically connects to a charging station, allowing the maximum operating period of approximately 18 hours to be extended to 24/7 operation. Two different commissioning software solutions ensure fast implementation of the vehicles. Another special feature is that the service is carried out by trained technicians, and the short repair and maintenance times ensure greater operational availability.

The fully automated Linde L-MATIC C pallet stacker with a load capacity of 1.2 tons, which will be presented as a near-series concept study at the intralogistics trade show in Stuttgart, is recommended for brownfield automation due to its short, narrow design. Especially in warehouse and production layouts that have grown continuously over the years, space is often tight or aisles are narrow. Measuring 1,785 millimeters in length and 840 millimeters in width, this pallet truck featuring a permanently installed lithium-ion battery is recommended in such cases as a flexible, scalable option for pallet transport that was previously carried out using larger, manually operated industrial trucks. This vehicle also comes with new software for commissioning. Instead of users having to program it themselves, the project logic is configured via a simple, clear user interface.

However, companies should not focus solely on the topic of automation, says Sales Manager Vieira. The digitalization of data, documents and processes is just as important. This can be achieved, for example, with the Linde Warehouse Navigator, which consists of a warehouse management, order picking and forklift guidance system. This software solution enables all orders, stocks and goods movements in the warehouse to be controlled, monitored and documented without the need for paperwork. 3D visualization provides an overview of the current occupancy for the entire warehouse and truck drivers are shown the fastest route to their destination. At the same time, the software documents all load carrier movements through changing storage locations.

read more