Autonomous Mobile Robots will contribute significantly to efficient and productive use of increasingly vital cold storage. This kind of automated solution is not a question of luxury but one of need, explains Frazer Watson, VP-Sales UK/Ireland at iFollow.

There are a number of factors that have tended to limit the effective deployment of automation in cold stores. But with design features addressing many of these issues, Autonomous Mobile Robots (AMRs) offer a way forward in applying automation to improve cold store efficiency and productivity.

This has become critically important given how issues such as Brexit, the pandemic, war in Ukraine and the weather have each highlighted the role chilled and frozen warehousing has in creating resilience in our food supply chains; not forgetting of course how Covid revealed the centrality of low temperature storage in medicine and pharmacology. Research and development and many advanced industrial processes also depend on the ability to maintain goods and materials at low temperatures.

Efficiency in everyway

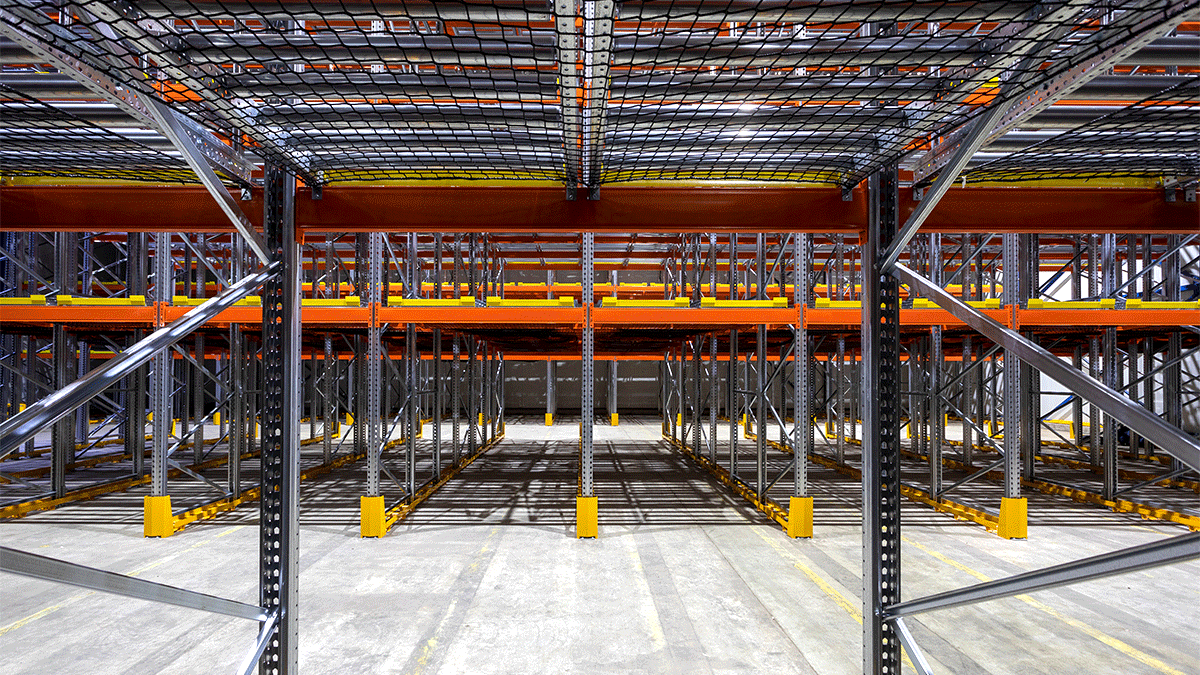

‘Efficiency’ here has several connotations. There is the efficient use of the available space. Many cold stores are quite small – often ‘cold rooms’ within larger buildings. But demand for cold space, from private companies’ own facilities to ‘public’ stores operated by a 3PL for multiple customers, is increasing. In the food chain in particular, companies from processors to distributors and retailers are looking for larger facilities – the Cold Chain Federation (CCF) has identified 678 units of over 50,000 square feet, and there are many that are much larger still. But cold stores are expensive to build and equip, and although the CCF recently estimated that some 16.7 million square feet of new space is under construction or being fitted out, that may not meet increased demand, especially as so much of the existing stock (34%) is over 25 years old and some of this is converted, not always very effectively, from other uses.

Cold stores must also be efficient in operation, which is key at a time of gas and electricity bills rising remorselessly. Although a well-built, equipped and run cold store uses a lot less energy than is commonly supposed, there is still an imperative to improve storage density and operations to minimise the heat coming in through open doors. And contrary to popular opinion, cold chain warehousing is not usually about minimally manned, long term, bulk storage. Many cold chains move goods in and out of store rapidly, and involve all the break-bulk, order-picking, stock rotation and other operations familiar from ambient warehousing. That has to be performed just as efficiently and productively, but in much more arduous conditions.

This means that labour, too, has to be deployed efficiently. Logistics UK last October claimed that “13 percent of traders are reporting severe warehouse staff shortages”; in November, the Cold Chain Federation noted “10 percent to 20 percent shortage rates” among its members. The pool of workers prepared to perform arduous, even hazardous, tasks in cold conditions is decreasing. In addition, there is an increasing realisation of the need to limit the length of time that workers spend in the cold before taking a break in warmer areas, and of the long-term impacts of heavy manual tasks in cold conditions.

Overcoming technical issues

Given all this, the cold store would seem an obvious arena for the introduction of automation. But this is not without its problems. There are technical issues – operation at low, and especially sub-zero, temperatures, can embrittle and otherwise degrade materials including metals, plastics, rubber tyres. Electric and electronic components can be affected by ice and condensation. Batteries, in particular, have degraded performance and shorter lives at low temperature. Fixed mechanisation, such as conveyors, takes up refrigerated space that isn’t being used to store the goods. There are safety and operational issues too – it isn’t easy to perform complex control operations, or to ensure that people are adequately protected from machinery, when workers are wearing heavy and cumbersome protective clothing and both their physical and mental agility may be compromised by the low temperatures alongside the hazards of condensation and ice.

Not all AMRs can work in cold storage. iFollow, however, has a range of robots for cold chain logistics that transport from 300 kg to 1500 kg payload down to -25°C and is specific to the cold store environment. This is due to its approach to safeguarding electronics and batteries. Temperature of key electronic components are regulated by an iFollow-developed servo system which eliminates condensation (and therefore, icing,) at temperatures as low as -25° – a particular issue when moving regularly between cold and temperate spaces. This also means that battery life is not degraded. Depending on the size of AMR, between 12 and 18 hours of autonomous operation are available from a 2-hour charge time. Fewer battery charges or changes obviously improve productivity, but also reduce the space needed for recharging.

Using AMRs rather than ride-on vehicles eliminates the known hazards of the latter – present in any warehouse operation but exacerbated in cold and slippery conditions. Specialised cold-store standard trucks are also not cheap.

Operator control is also suited to cold store conditions. It is not reasonable to expect workers to input complex instructions while wearing heavy gloves or to require them to take their gloves off for extended periods. The Mycelium WCS web app from iFollow, which is compatible with all available WMS/ERP systems, can be used through any computer or smartphone with most instructions available through just one or two clicks.

AMRs do not require the segregated space of conveyor-based systems and they can turn in their own footprint, unlike most AGVs which require a defined bend to corner. This maximises storage space, or to put it another way, minimises the volume of fresh air being refrigerated. Also unlike AGVs, AMRs do not require semi-permanent predefined pathways, thus allowing a more flexible use of warehouse space. They also do not require especially smooth and even floors – an issue with some older or converted cold stores – indeed, implementation doesn’t usually require any expensive infrastructure at all.

An ability for an AMR to carry two roll cages at once, to a maximum load of 1,500kg offers an advantage, particularly in the cold store environment because it reduces the number of times doors have to be opened and closed. That not only reduces energy loss and minimises the potential for condensation, but reduces the hazard from the, typically, fast acting cold store doors.

Collaborative order picking

The AMRs are designed with safe, collaborative use in mind. Lidar navigation prevents the vehicle from colliding with permanent fixtures, with goods left blocking aisles, or of course with the attendant workforce (who, clad in thermal headgear, may not always be aware of the traffic around them). Typical maximum speed is 1.7m/s – a brisk walking pace – with linear and angular speeds and accelerations closely controlled.

In typical order-picking use, one operator might work with two AMRs within a defined pick zone, selecting items to roll cages or destinations. The operator can receive pick-list instructions by voice terminal, RF terminal or tablet, and of course the AMRs are simultaneously receiving their complementary movement instructions. Picking this way can yield 90% better productivity than the conventional manual approach, while optimising the picker’s movements. AMRs can equally be used for the variety of shuttle movements required in the store, moving goods between locations. Trough an intuitive fleet management interface, the scenario can be simply generated, and the robotic system works out the movements required.

AMRs, then, can improve the efficient use of cold store space both by increasing productivity and minimising ‘wasted’ space. The latter, along with reduced door openings, helps with energy efficiency, as does the non-degrading battery performance. The efficiency of scarce and increasingly expensive labour is maximised, and perhaps most importantly, the safety and welfare of both goods and staff is addressed. There is a clear logic in letting AMRs carry the load in cold stores.