Autonomous mobile robots optimise the movement of goods in warehouses, logistics centres and manufacturing plants. The internal transport of goods is a core element of companies’ logistics operations. AMRs are intelligent vehicles designed to move loads independently, without the need for human guidance.

These high-tech machines plot their routes using virtual warehouse maps, performing their assigned tasks with the utmost efficiency. Moreover, they are equipped with innovative navigation software that enables them to identify and avoid obstacles. This technology ensures safe coexistence with other machines and people sharing the workspace.

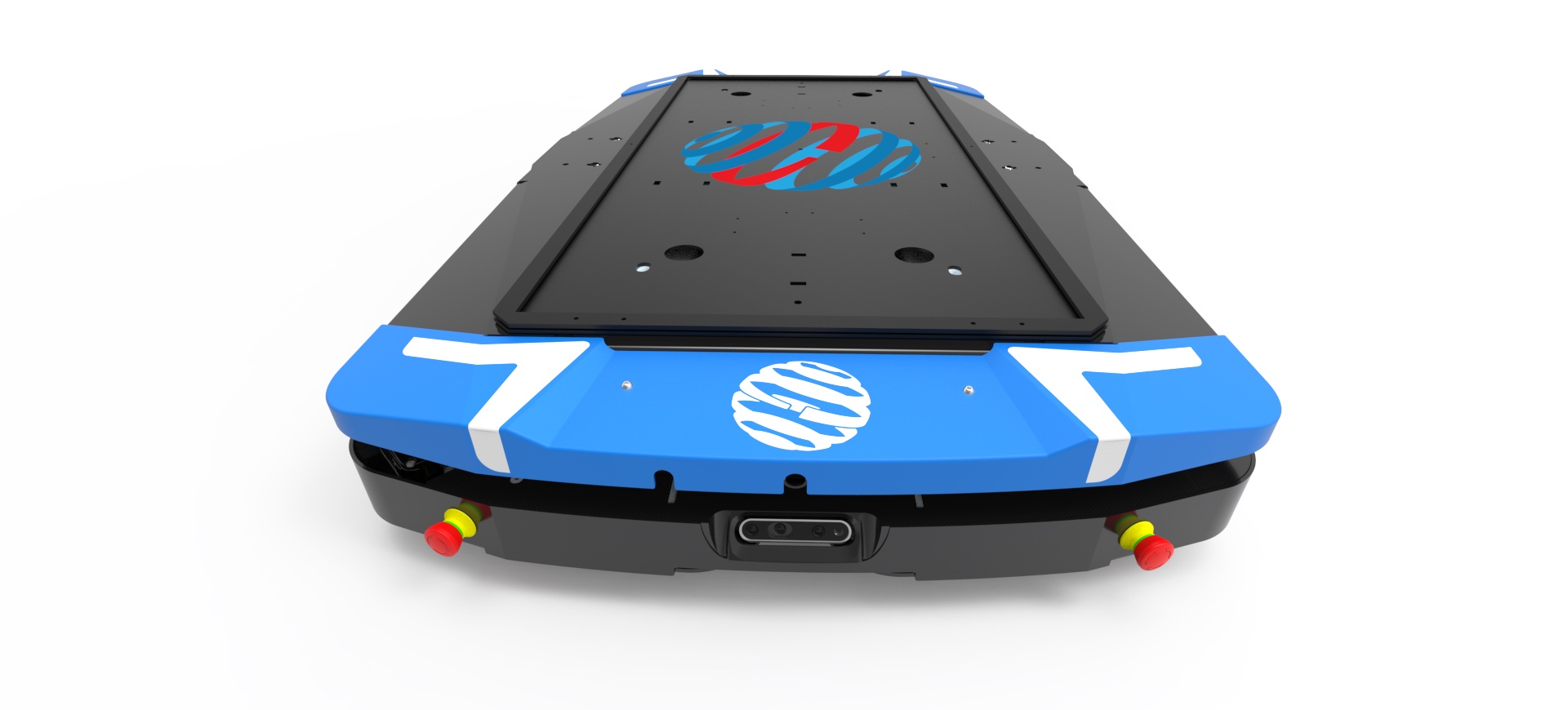

Mecalux’s AMR line features models to manage a wide variety of loads, from boxes, totes, bins and trays to pallets and shelving. The integration of these systems significantly contributes to optimising intralogistics processes.

Meet the Models

Mecalux’s range of AMRs can handle goods weighing between 100 and 1,500 kg, making them a versatile solution adaptable to a multitude of logistics environments:

• AMR 100 Multi-Box: Incorporates a mast to transport bins, boxes, crates and trays. Maximum payload: 100 kg

• AMR 100 Box: Equipped with a conveyor to transfer boxes, trays and packages. Maximum payload: 100 kg

• AMR 600 Rack: Designed to move shelving units to pick stations. Maximum payload: 600 kg

• AMR 1500 Pallet Lifter: A lifting system transfers pallets to and from fixed platforms and conveyors. Maximum payload: 1,500 kg

• AMR 1500 Pallet Conveyor: Outfitted with a conveyor to transport pallets to the various warehouse areas. Maximum payload: 1,500 kg

AMRs can carry out a wide variety of tasks in all kinds of facilities and offer an excellent opportunity for boosting efficiency and productivity in picking. They can be integrated in three working methods:

• Goods-to-person: These devices supply pick stations with the goods required to fill orders.

• Rack-to-person: The mobile robots transport picking shelves to operator workstations.

• Person-to-goods. AMRs assist employees when locating products in the warehouse by freeing them from using picking carts.

Internal Material Transport

AMRs replace or complement handling equipment such as forklifts, conveyors and electric monorail systems. Mobile robots make product transfers more flexible: they automatically adapt to modifications made in logistics facilities. AMRs can reconfigure their routes in the event of changes in workspace layouts, racking/shelving arrangements or any other adjustments within the warehouse.

By quickly adapting to fluctuations in demand or workflow, mobile robots help companies stay competitive in an ever-evolving logistics environment. AMRs also optimise order shipping and other outbound processes. Once orders have been filled at the pick or consolidation stations, the AMRs move them to the shipping area.

By following streamlined routes and working autonomously, the robots ensure that orders are moved efficiently and promptly. AMRs – for both light and heavy loads – automate the delivery of parts, components and raw materials to work and assembly stations on the production lines in various industries.

The ability of mobile robots to adapt to dynamic environments makes them suitable for operational areas requiring flexibility and agility. Automation also reduces downtime and increases throughput in manufacturing processes.

similar news