Re-brands are sensitive and critical operations and the warehouse automation sector is no exception. David Priestman attended the launch of Movu Robotics in Belgium, late September.

“Automate, in a easy way, the distribution centres of our customers. Democratise automation.” This is the mission statement espoused by Jos de Vuyst, CEO of stow Group, at the launch of Movu Robotics, formerly known as stow Robotics. With a large existing client base for its racking, storage, silo and rack clad products stow Group is well-positioned to sell and integrate robotics and automation technology. It can scale-up fast.

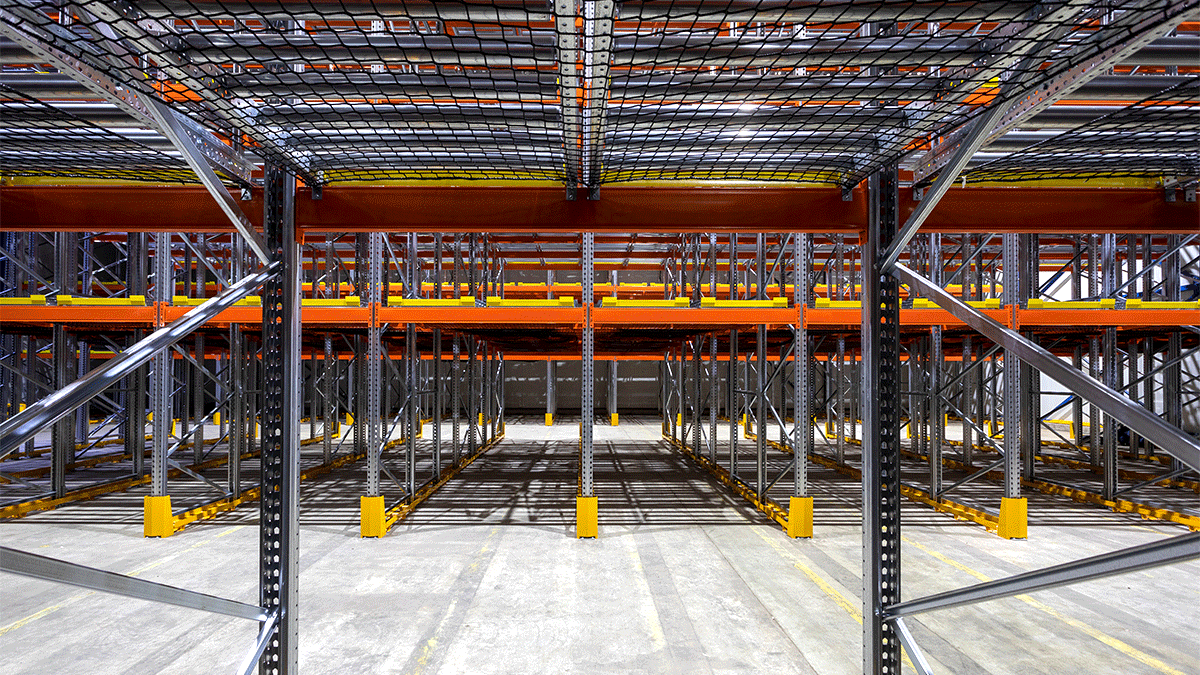

The company wants to help these facilities transition to automated operations, thereby not leaving any warehouse behind in the darkening warehouses of the future. “Plug and play, dense, low-energy usage systems with fast deployment,” is the offering, according to de Vuyst. Automation provides a productivity boost and is scalable, with no need for new warehouse infrastructure.

The rationale for a new brand name – Movu – is because the ‘stow’ name is perhaps too associated with rack and storage – traditional materials handling. Disconnecting from this and switching to a ‘catchy’ new brand fits the mission statement. Employing more than 300 employees by the end of this year across Europe and the US, Movu Robotics expects order intake of more than €300 million in 2023.

The Movu Robotics portfolio comprises automated storage, picking and transport for pallets, bins and items, offering an easy buying journey, competitive pricing, cost savings, quick delivery, high density storage and space optimisation. The portfolio allows end customers and integrators globally to benefit from a seamless and user-friendly warehouse automation ecosystem.

The portfolio includes:

• ‘Movu atlas’ – Pallet shuttle for multiple deep storage

• ‘Movu ifollow’ – slimline AMR for collaborative picking or transport of pallets, made near Paris. A unique selling point of ifollow is that it works in deep freeze areas of a warehouse.

• ‘Movu escala’ – Robotised 3D storage and fulfilment system without lifts

• ‘Movu eligo’ – Integrated picking robot arm

All Movu systems are controlled and managed via their own warehouse execution software (WES).

The impressive, iconic headquarters in Lokeren, situated between Antwerp and Ghent, combines modern offices with manufacturing operations for atlas and escala robots (500 per week) under a single roof. There is also an experience centre – one of the biggest in Europe – where the latest technologies are showcased live to customers and partners. One factor in choosing its location is the desire to partner with local Universities to recruit young engineers.

I asked de Vuyst to describe the journey taken by stow Group leading to the launch of Movu Robotics:

“Since 1987 stow Group has grown rapidly into a €1 billion global company that today ranks among the top two racking manufacturers in the world. Originally a family-owned company, then owned by Kardex for a decade, a management buyout in 2013 was backed by private equity funding. The racking business of stow stands out in the sector by having a production footprint spanning Europe with 10 racking factories and a network of 20 sales companies giving direct access to, and close contact with, the customer. Our racking solutions are customised around standard products, enabling us to have highly automated factories. This results in stow being a cost leader as well as fast growing and very profitable.

“stow Robotics was born the day we started writing Warehouse Control Software (WCS). We are now developing our own WES suite and control software on the machines, which we build ourselves. We will not develop our own WMS as it is too complex. We are evolving into a supplier that can provide an automated pallet warehouse, from a small scale operation up to large projects. The investment climate is softening a bit, big investment decisions are taking a bit longer, due to high interest rates.”

Will we see ‘Dark Warehouses’ (without workers)?

“I’m a big fan in principle. The ideal is racks and robotics, but you must go high. Labour is disruptive, people often hate working in warehouses. Forklift usage is falling, as will conveyor coverage and manual picking. We have the products to achieve a dark warehouse via four or five main technologies.”

How is Movu Robotics positioned in the market?

“We expect double-digit growth. The global material handling equipment market size is forecasted to reach $350 billion by 2030, driven by AS/RS systems and robotics. By our Movu Robotics positioning and portfolio we are very confident of becoming an essential player in this market. Movu Robotics will follow the same development path as stow Racking, so we will build a network of sales companies in the main territories allowing us both channels to the market: direct and through integrators – not just to new customers, like competitors do.

“Where many companies are built around one automation product, we have an integrated ecosystem of scalable, automated warehouse solutions for pallets and bins. That’s quite rare, and the portfolio will continue to grow. We will take a deep dive into some vertical markets and develop specific automation products for particular sectors. One trend is third party logistics operators beginning to automate. We’re strong in cold stores, pharmaceuticals and food logistics.

“We want to offer the possibility of automation to SMEs that have a few thousand pallet locations. While bigger projects are generally more complex, a straight forward pallet project of, for example, 80,000 pallet locations requiring 60 shuttles has a low complexity and fits our profile. If, however, that same warehouse had sorters, a mix of complex software and machines we don’t have in our portfolio, then we’d defer to a systems integrator.” Movu does not offer robots-as-a-service as the company offers a broad range or solution.

Supermarket of Materials Handling

How do the business units in stow Group benefit from each other?

“stow Racking and Movu Robotics together are a unique one-stop-shop with proven interfaces that combines best of racking and robotics. Sales is another of the most important synergies between stow Racking and Movu Robotics, with many leads for automation coming via the racking side, which has 10,000 customers across Europe and US. Many of these customers take the decision at some point to automate their operations. stow Racking has more than 200 sales people globally, which also bring leads for robotics and automation products.

“Movu Robotics benefits from having the strength of stow Group behind it, with all of its management experience and expertise. Another important factor is the backing of Blackstone, a private equity company with a vast experience in logistic real estate, who are very supportive. Also, stow Racking activity successfully generates cash, fuelling growth in Movu Robotics without the need for continual equity rounds.”

How does the company’s culture drive development?

“While stow Group has become a large organisation, with a well organised corporate structure, it still has the dynamics of an SME company. We have direct contact with our people through a relatively flat management structure, which gives an agility and dynamism that is popular with our customers. This allows us to attract talent to support our know-how in engineering, software and other departments. Joining Movu Robotics is more akin to working in a start-up than a corporate environment. While enjoying an agile environment, staff also gain the support of being in a solid company.”

Where do you see the stow Group and Movu Robotics in five years?

“stow Group will continue to grow the racking business, we will definitely not lose interest in the racking business. Racking is an essential and profitable part of the Group, so it is important that it continues to grow. Having established stow as a racking market leader in Europe, with approx. 30% market share, we started to build the US business over the past 18 months, where there is huge potential. We have created a sales office in Chicago and have just taken the decision to build our first racking plant in the US – the location is not yet fixed. With strong sales in this market, it no longer makes practical sense to ship containers of racking across the Atlantic. We’re not excluding the Asian market later on in the future, just not now.

“Of course, we will continue to grow Movu Robotics. While entering the market with systems that are easier, standardised, scalable, and flexible, in the next five years we will be tackling more complicated projects. I think in five years’ time, Movu Robotics’ activity will be equivalent to, or even exceed, that of stow Racking, creating two very strong legs for the stow Group.”

What about further acquisitions and new products?

“Coming from a manufacturing background, doing things ourselves is in our DNA. We will develop our own technologies as much as possible, only seeking partnerships when we don’t have the time to develop them ourselves. For example, it makes no sense to start developing vision technology on our own. In such cases we will partner with an appropriate supplier or licence it in. AMRs with forks or for bins and gripping technology are interesting. The sales side is different because we want to grow as fast as possible and whilst we are developing our own sales network are open to work together if we find a good partners for specific regions.”