5G-technologies could deliver significant carbon savings across food and drink manufacturing from farm to fork, according to new economic modelling. The modelling reinforces the environmental benefits of 5G Standalone (5G SA), particularly for key industries in that are traditionally carbon intensive like manufacturing.

Technologies like Internet of Things (IoT) sensors and tracking systems can transform the way we manage food and drink across the manufacturing supply chain – from its origins on the farm, through to factory production sites and transporting the food on UK roads to our stores. The new modelling reveals that 5G technologies could save the food and drink supply chain 37 million tonnes of CO2 equivalent emissions between 2024 and 2035. That’s the same as removing 78,000 delivery trucks from UK roads.*

However, these efficiencies can only be achieved with the timely rollout of a 5G SA network. That is why, following completion of the proposed joint venture, Vodafone UK and Three UK have committed to investing £11 billion in the first 10 years as a combined business which will help deliver 99% of 5G Standalone population coverage by 2034. This critical infrastructure will deliver a far superior network that will allow us to build towards the UK’s digital future, faster and facilitate the innovations needed to support the UK on its Net Zero journey.

The modelling conducted by WPI Economics for Vodafone reveals the impact that these technologies can have on decarbonising the supply chain.

• In farming, 5G technologies, such as drones and sensors that monitor soil and crop conditions could improve yields and significantly reduce the food waste produced on farms. By 2035, this reduction in food waste can correspond to a total saving of carbon emissions equivalent to 6% of the UK’s greenhouse gas emissions in 2022.

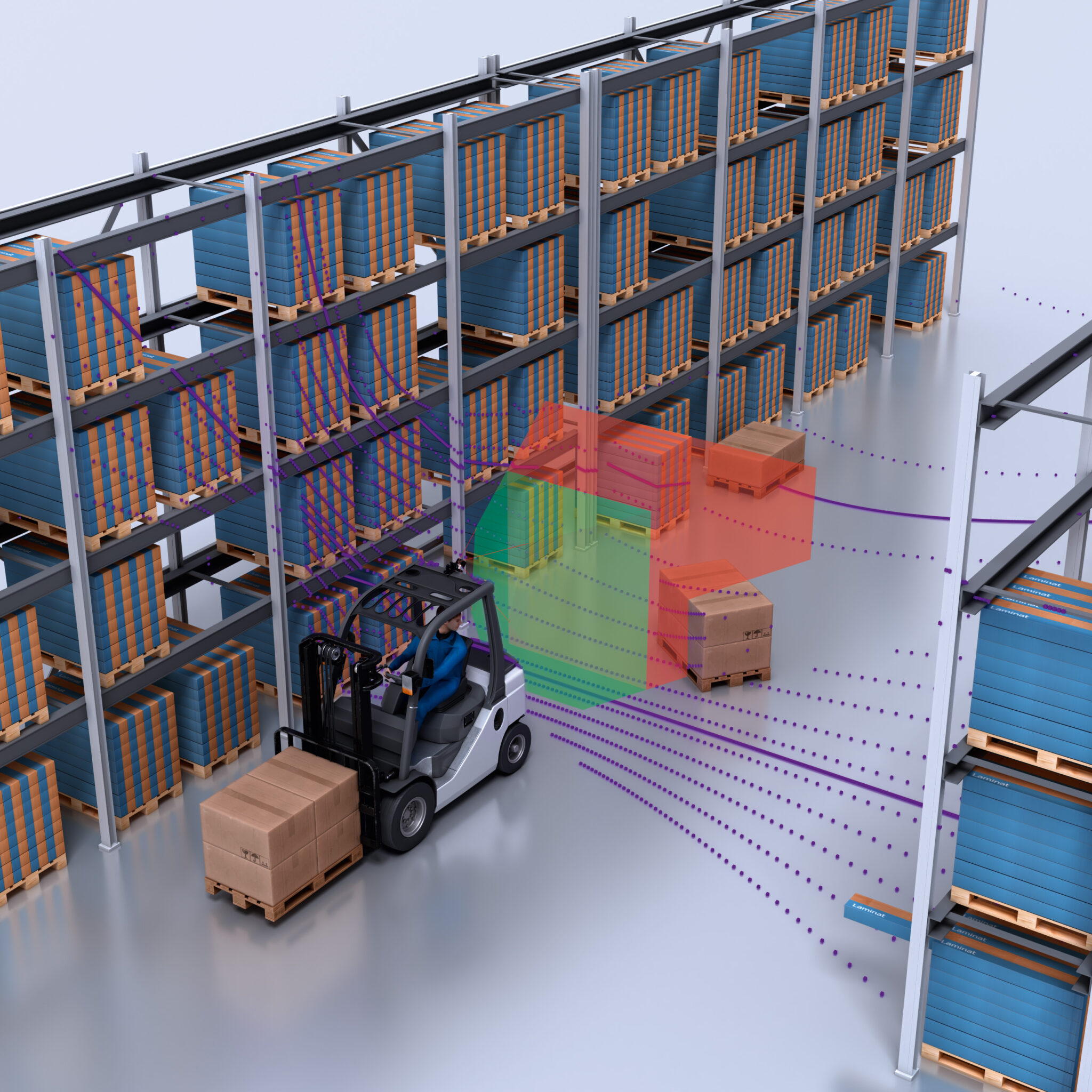

• On the factory line, 5G-enabled manufacturing technologies like remote maintenance systems, which reduce machine downtime, plus IoT tracking systems, which reduce electricity consumption required for cooling and storing goods, could all contribute to an 11% reduction in CO2e emissions in manufacturing by 2035.

• When transporting goods by road, implementing 5G technologies, such as Vehicle-to-Everything to improve the fuel efficiency of Heavy Goods Vehicles (HGV), in the commercial distribution of food and drink could reduce HGV emissions by up to 54 MtCO2e. This equates to more than double the total UK HGV emissions of 2021.

Andrea Dona, Chief Network Officer, Vodafone UK, said: “We’re supporting many customers across the farm to fork supply chain to become more energy efficient through innovative technology like IoT and the Cloud. But we need the proper infrastructure to take it to the next level. 5G Standalone has the potential to transform the UK supply chain, smoothing operations for suppliers and reducing carbon emissions. Vodafone’s proposed combination with Three UK will enable us to invest £11bn over the next decade, reaching over 99% of the UK population with 5G Standalone by 2034 and helping the UK’s agricultural industry decarbonise sooner rather than later.”

A spokesperson from the Road Haulage Association (RHA), said: “The RHA is dedicated to supporting its members to help them sustainably reduce emissions in the road freight and logistics industry. We welcome Vodafone’s newly released research which finds that the implementation of 5G technologies could reduce greenhouse gas emissions in the sector by up to 44%. This year, the RHA launched the Net Zero forum which seeks to collaborate with other leading business voices for sharing best practices, technological advancements, and cutting-edge research related to sustainable transport, and we look forward to continuing to support our members by identifying new technology which will support them to decarbonise.”

In June, Vodafone launched the UK’s first Standalone network, 5G Ultra, creating one of the most technologically advanced network for customers.

Methodology

The estimated figures are based on analysis by WPI Economics using trusted data sources, including data from the Department for Energy Security & Net Zero, Department for Transport and the ONS, as well as academic literature. Overall benefits are calculated based on a Theory of Change flow, which breaks down the total effect into discrete effect channels identified through a literature review. Benefits coming from each channel are estimated and summed together (where applicable). The analysis presents emissions avoided between 2024 and 2035, assuming a staggered implementation of 5G-enabled solutions over time. The estimates are based on official government projections of CO2e emissions by industry, and the projected changes in sources of energy generation.

*Delivery trucks refers to Heavy Goods Vehicles (HGVs).