In a commercial relationship that combines both innovation and efficiency, AR Racking has successfully completed its latest collaboration project with Nordfrost GmbH & Co.KG to optimise refrigeration logistics processes. This strategic partnership reflects the growing need for advanced storage solutions that can handle the unique challenges of cold chain logistics, particularly in the demanding environment of deep-freeze storage.

“This project is a test of the ability of our solutions to meet the specific requirements of deep-freeze logistics,” said Kai Thiemann, Key Account Manager for AR Racking Northern Germany. “We are delighted to have been able to generate operational improvements for our customer with the successful implementation of the LIFO AR Live Storage system. This project demonstrates how we can adapt our systems to the specific needs of our customers, ensuring maximum efficiency and streamlined operations.”

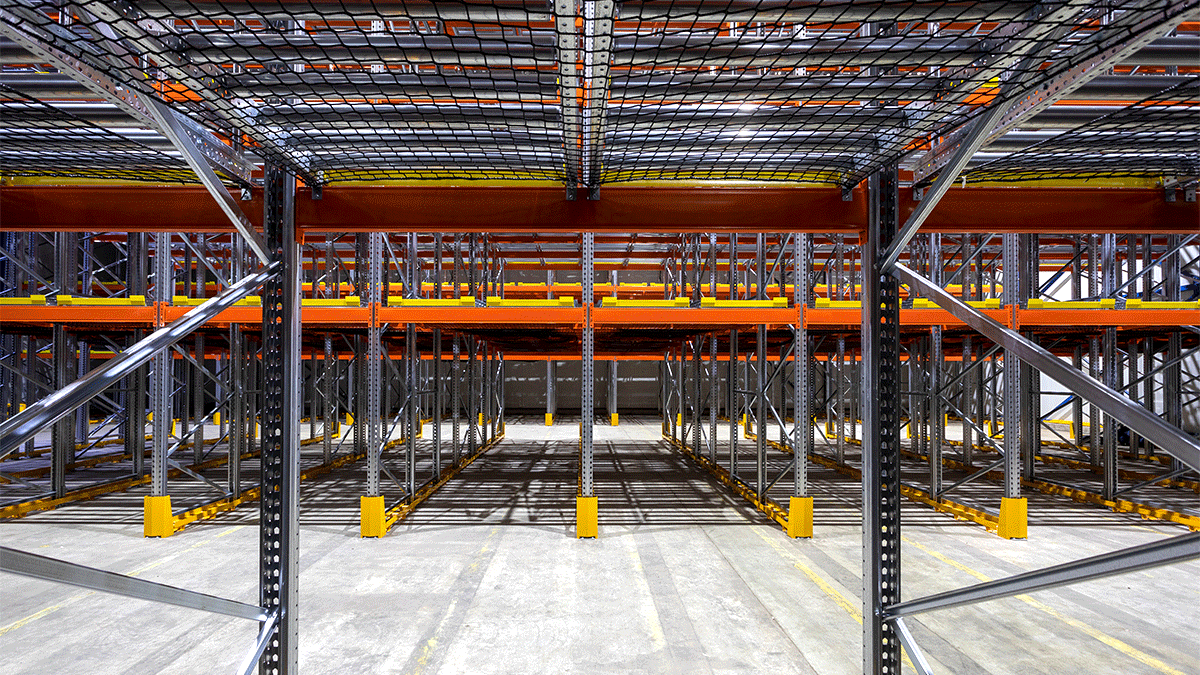

The project was rolled out in two phases. In the first phase, the system was installed across an area of 840 m², allowing Nordfrost to use the system immediately in a partial area, which helped them start storing goods without delay. The early start was crucial for ensuring minimal disruption to their ongoing operations. Following the success of this initial phase, a second phase was implemented, covering an additional 630 m². This marked a further step in the modernisation of the storage system, enabling Nordfrost to enhance its overall logistics efficiency.

The successfully implemented project complies with stringent cold storage standards and demonstrates the flexibility, robustness, and high performance of the AR Live Storage LIFO system, specifically tailored for deep-freeze conditions where maintaining product quality is paramount. The adaptability of the solution shows AR Racking’s capacity to meet industry-specific requirements, offering clients like Nordfrost a competitive edge in their operational processes.

Oliver Kellner, director of the Nordfrost subsidiary in Hann. Münden, added, “The new push-back system complements our logistics processes at the plant and allows for better use of existing storage capacity. It has enabled us to optimize how we manage and move our stock, particularly in terms of handling perishable items in a timely and efficient manner.”

This collaboration not only highlights the operational benefits of advanced storage systems but also serves as a model for future cold storage projects where efficiency, flexibility, and compliance with strict standards are critical for success. The project underscores how modern logistical solutions can transform operational capabilities in industries with demanding storage conditions like deep-freeze logistics.

Read Similar…

3 Essential Strategies to Face Peak Season in a Sustainable Way