AR Racking, leader in industrial storage solutions, is pleased to announce the successful installation of an adjustable pallet racking system for Buencafé Liofilizado de Colombia in Chinchiná, Caldas. The project, which covers an area of 5,280 m² and provides 4,344 pallet positions, represents a significant milestone in optimising the storage and logistics of the renowned coffee producer.

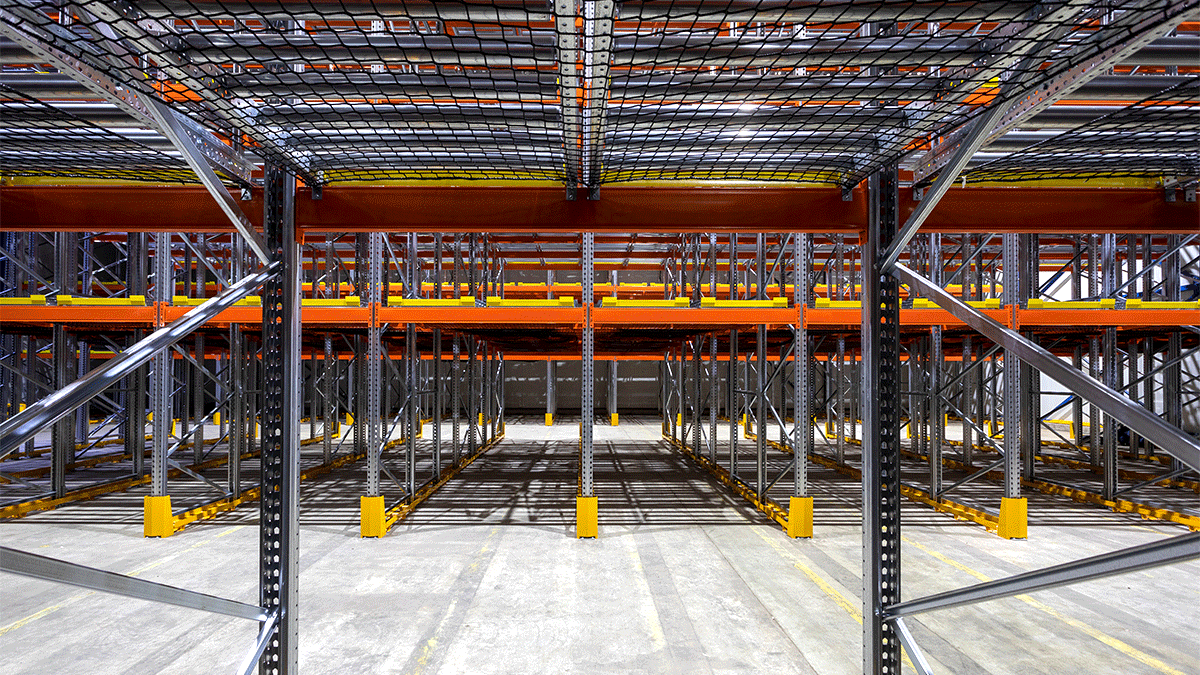

The solution implemented by AR Racking is characterised by its robust and versatile design, able to adapt to the specific needs of the coffee sector. The double-deep adjustable pallet racking system, with 4 beam levels, together with the earthquake-resistant structural calculation, guarantee safe and efficient storage of Buencafé’s products, even in areas of high seismic activity.

“We are very satisfied with our partnership with AR Racking on this project”, commented Alejandro López, Engineering Director of Buencafé. “Its experience and professionalism have been key to the success of the installation, and the new storage solution will allow us to optimise our logistics and increase our production capacity.”

For his part, Edward Suescun, Project Manager at AR Racking, highlighted the importance of this project for the coffee sector: “At AR Racking we are committed to developing the Colombian coffee sector, and this new installation is an example of how our storage solutions can help companies improve their efficiency and competitiveness.”

AR Racking is part of Grupo Arania, an industrial group of companies with extensive experience and scope, and with a multi-sectoral activity based on the transformation of steel that dates back more than 80 years. AR Racking provides the market with a wide range of solutions with high certified quality standards and a comprehensive project management service. AR Racking’s industrial storage systems stand out for their innovation, reliability and optimum efficiency.

similar news